High Voltage Transformer

The high voltage transformer steps up medium-voltage power to grid voltage of 66kV and vice versa.

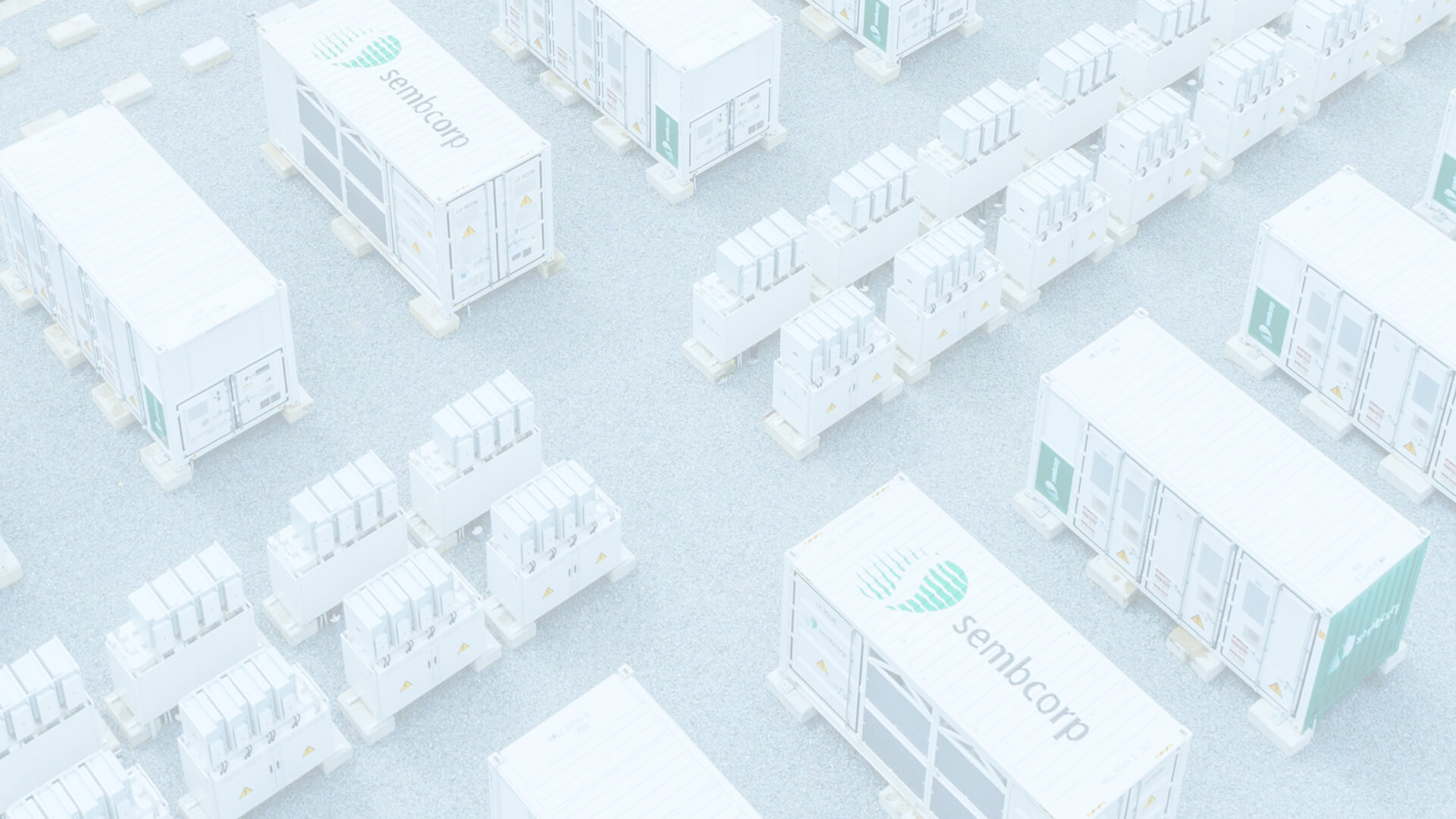

Battery Energy Storage System (BESS)

Huawei BESS is an all-in-one system that integrates power supply and distribution, monitoring, environment control, and fire extinguishing system, etc.

Each container contains Lithium Iron Phosphate (LFP) battery packs. Built-in air conditioning systems keep the batteries at optimal operating temperature.

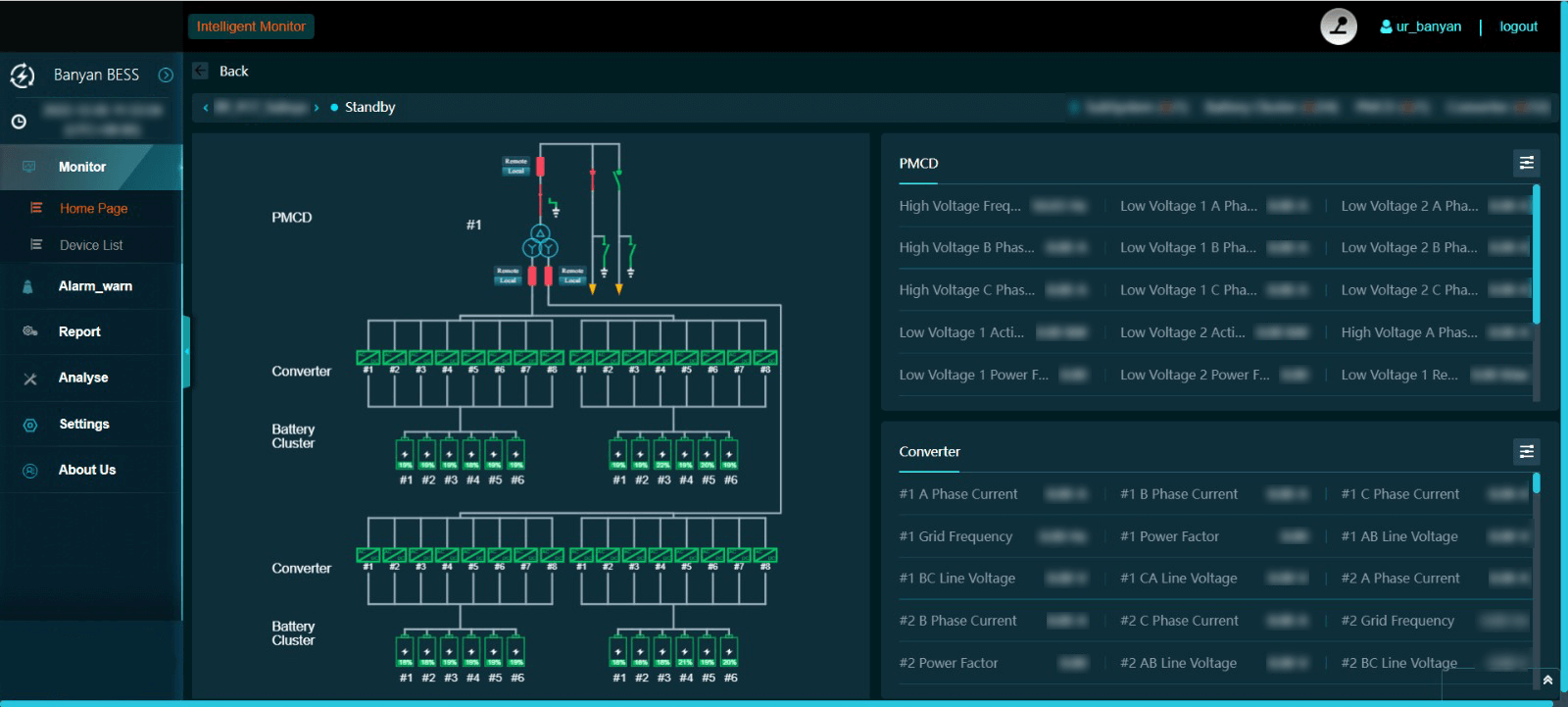

Local Control Room

The Central Control System is located here where the batteries charge and discharge cycles according to grid needs.

With remote access capabilities, security cameras provide live monitoring, and dashboards track performance indicators such as internal temperature and battery health conditions.

Power Conversion System (PCS)

The bi-directional Power Conversion System (PCS) uses power electronics technologies to convert the direct current (DC) power from the ESS into alternating current (AC) power for the grid, and vice versa.

Smart Transformer Station

The transformer room is used to convert the LV AC power into the MV AC power.

The main equipment is a transformer configured with gas, oil temperature, pressure, and oil level protection. A comprehensive protection device is also configured in the MV room for the transformer.

Local Control Room

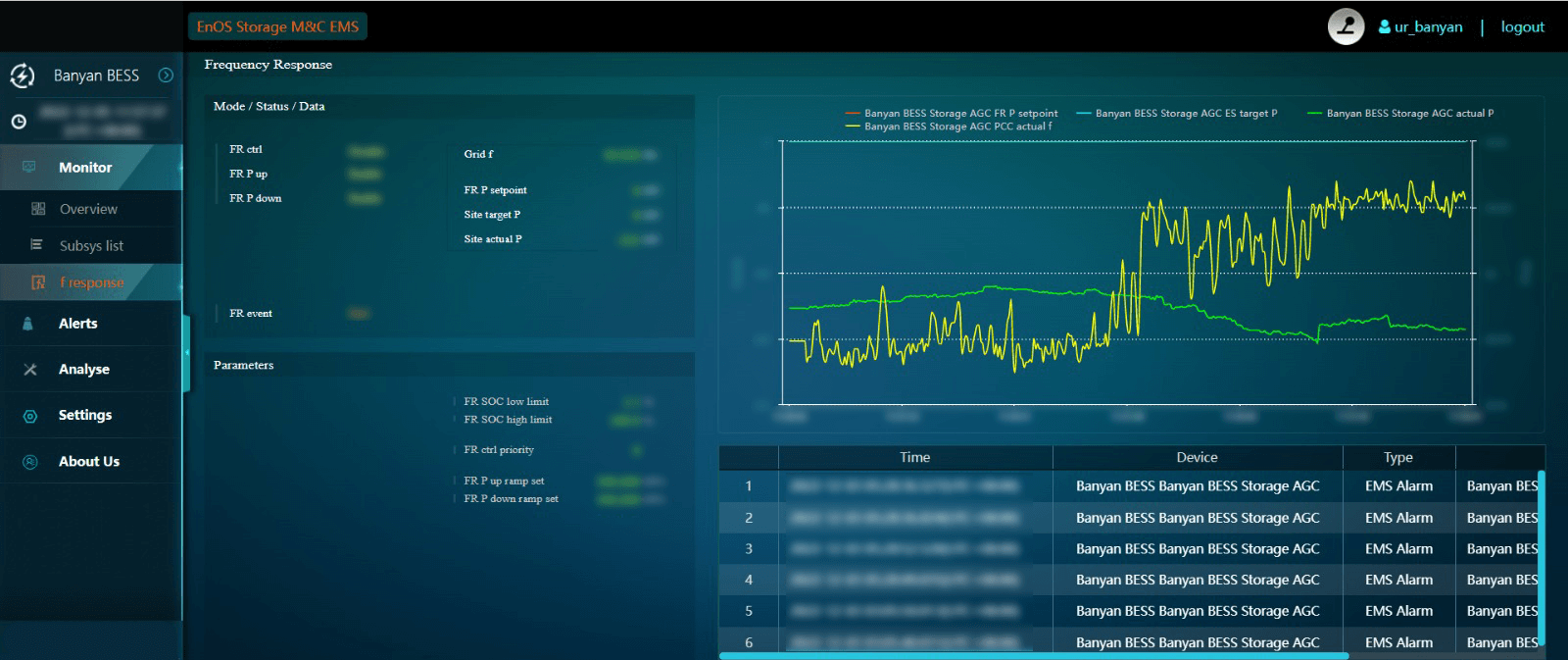

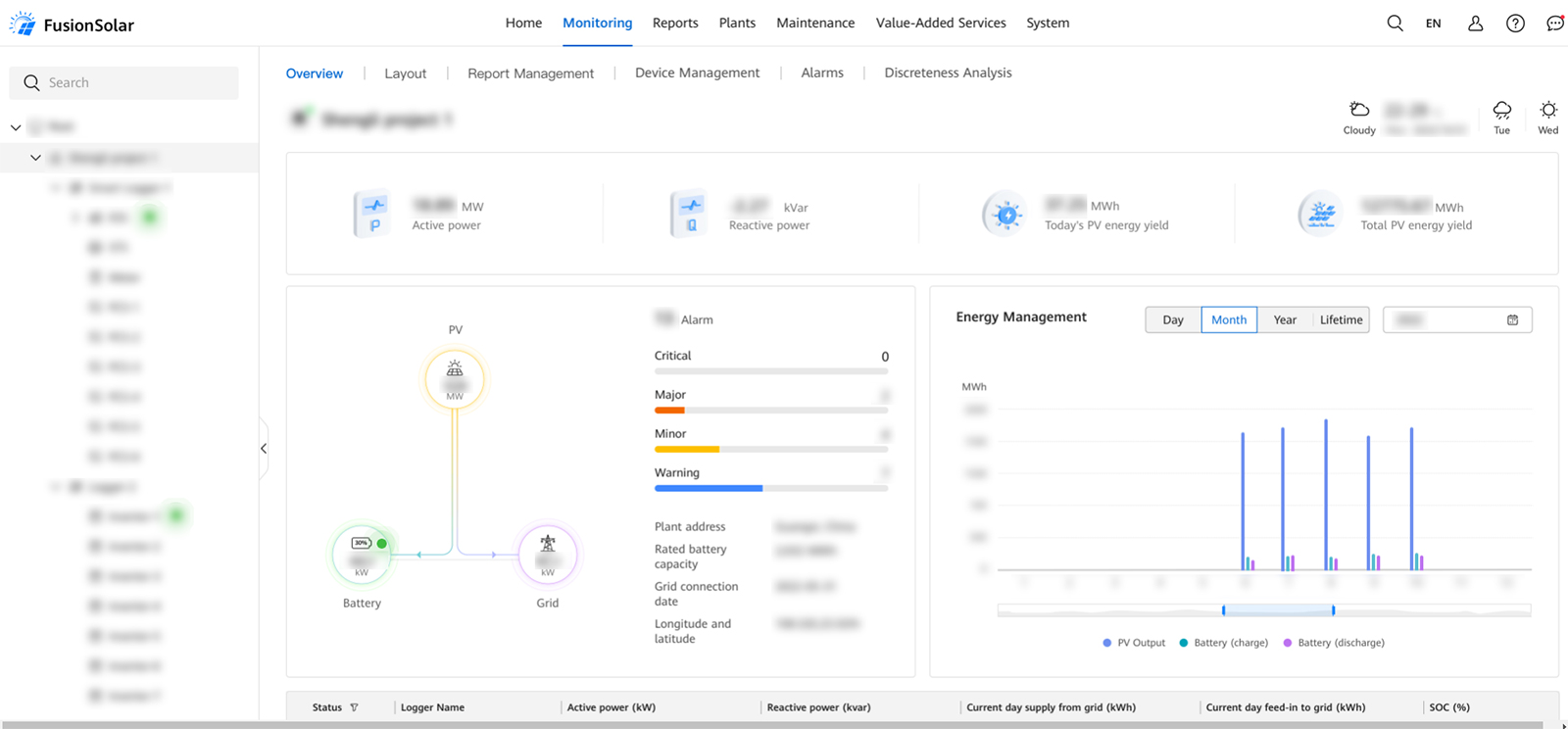

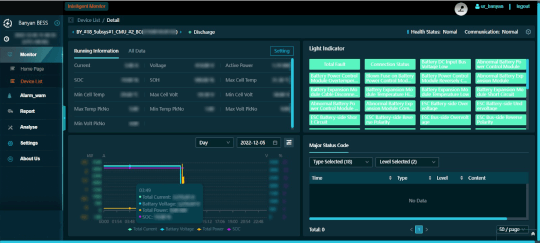

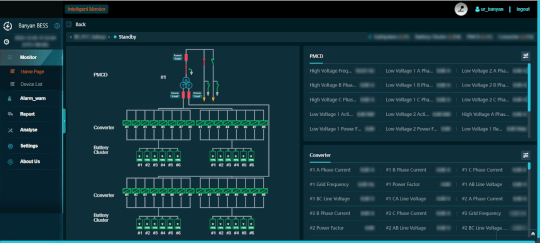

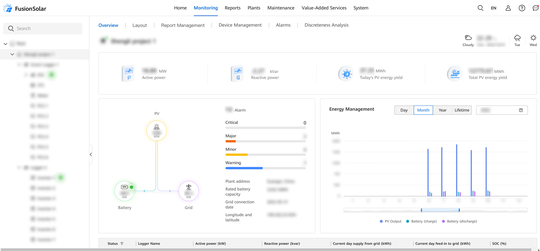

Energy Management System

Energy Management System (EMS) receives and executes various dispatch instructions for ancillary services.

Local Control Room

Energy Management System

Energy Management System (EMS) receives and executes various dispatch instructions for ancillary services.

Local Control Room

Energy Management System

Energy Management System (EMS) receives and executes various dispatch instructions for ancillary services.

Local Control Room

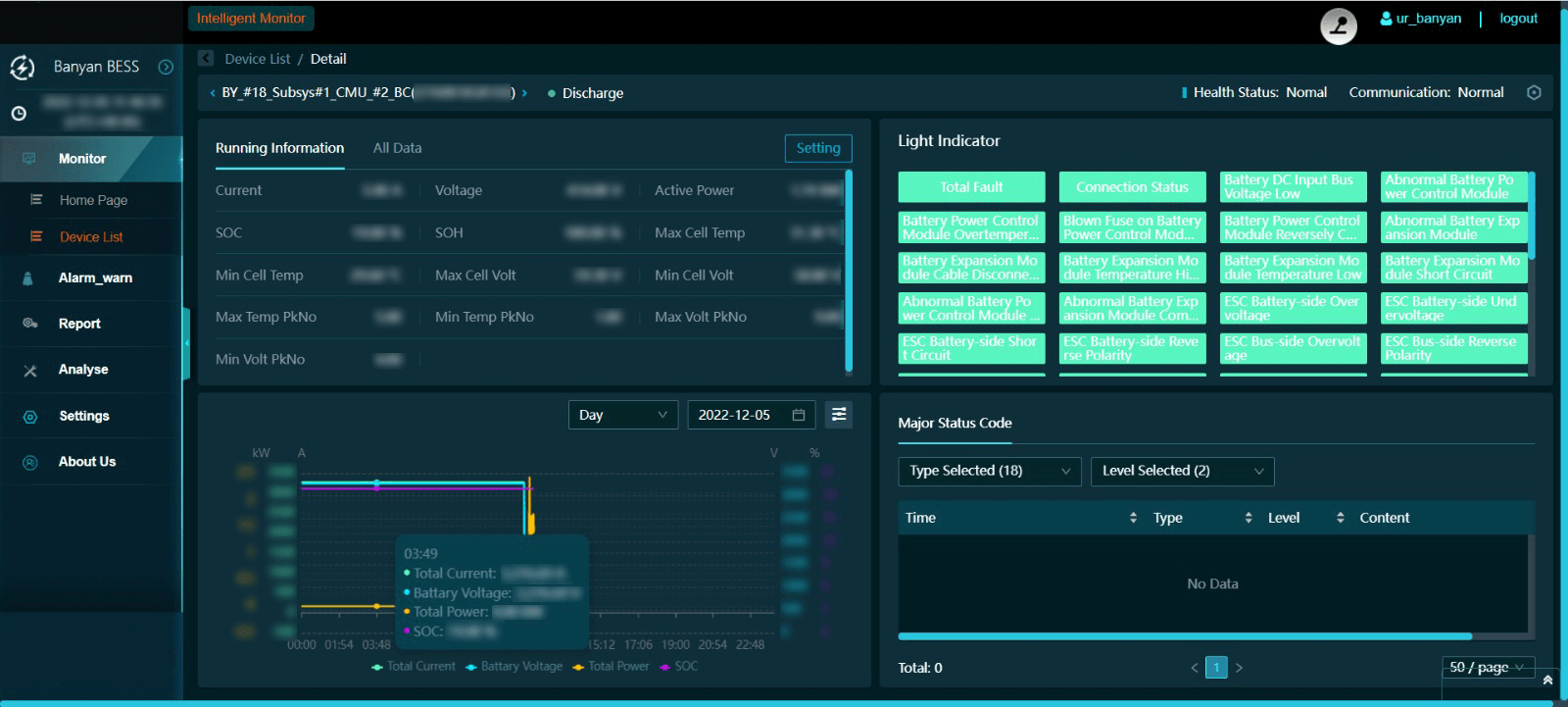

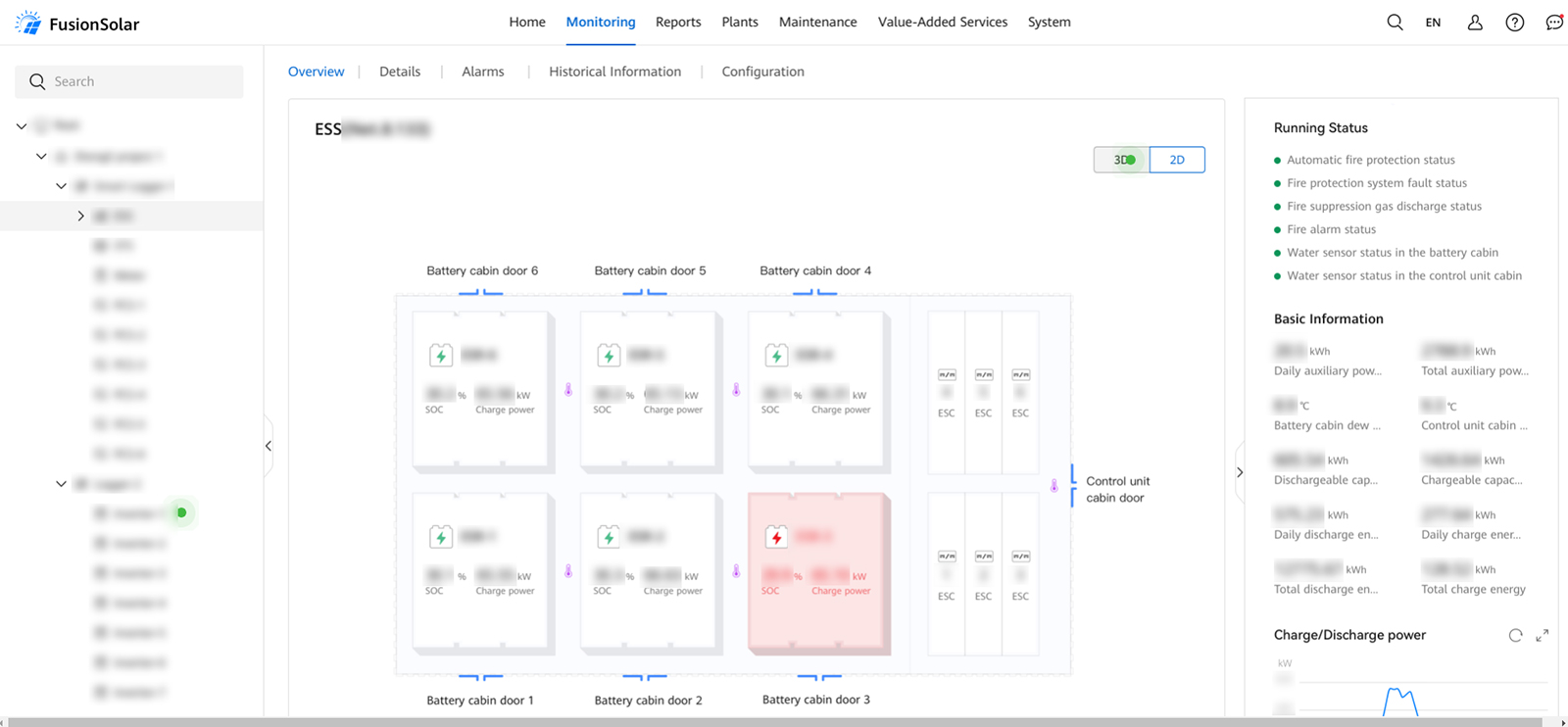

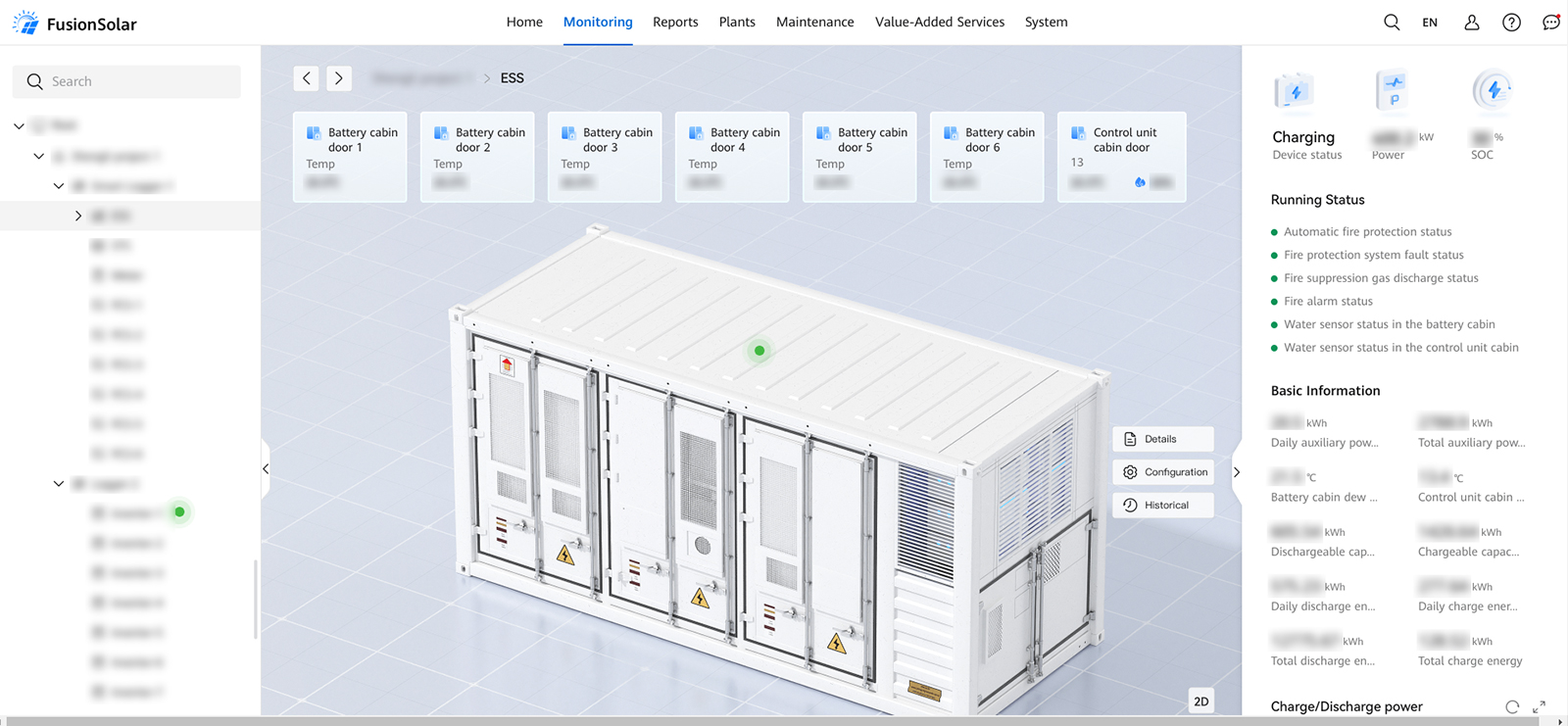

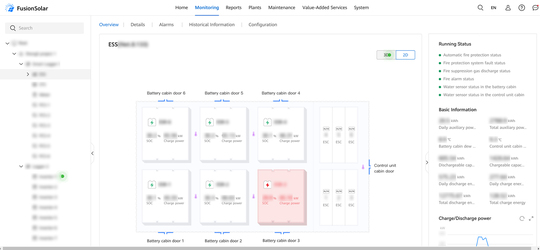

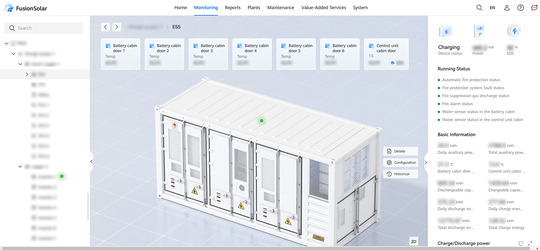

Battery Management System

3D BMS makes operations and maintenance easier and real-time data more intuitive, including battery cell, pack, rack information, HVAC system status, and so on.

Local Control Room

Battery Management System

3D BMS makes operations and maintenance easier and real-time data more intuitive, including battery cell, pack, rack information, HVAC system status, and so on.

Local Control Room

Battery Management System

3D BMS makes operations and maintenance easier and real-time data more intuitive, including battery cell, pack, rack information, HVAC system status, and so on.

Local Control Room

Battery Management System

3D BMS makes operations and maintenance easier and real-time data more intuitive, including battery cell, pack, rack information, HVAC system status, and so on.

Battery Cabin

Pack-Level Optimization

Firstly, the pack optimizer improves the battery charge and discharge capacity. When one battery pack is fully charged or discharged, it will be bypassed by the pack optimizer automatically so that other packs can continue charge or discharge.

Secondly, by having the pack optimizer, every battery pack can be calibrated automatically and avoids system shutdown.

Battery Cabin

System Protections

Smart Safety Pre-warning is used to identify gradual failures. Across the failure path, the pre-warning function can identify potential faults.

To prevent thermal runaway spread at the system level, one important measure is to set up multiple isolation and shutdown mechanisms. Huawei provides four levels of active shutdown and two levels of passive isolation for battery packs, battery racks, and the system to disconnect faulty internal circuits and prevent faults from spreading.

At the battery pack level, Huawei uses the board BMS and energy optimizer to isolate the faulty pack by software and hardware. At the battery rack level, Huawei uses the BCU and rack controller electronic switch to implement active shutdown and isolation. At the system level, Huawei uses circuit breakers and fuses to implement passive isolation.

Battery Cabin

Distributed Cooling

Distributed air conditioners individually cool each rack, together with mix-air tunnel inside the pack.

Battery Cabin

Rack-Level Optimization

Smart rack controller adjusts the BUS-side voltage of each rack and makes each rack independent, where rack capacity can be fully utilized for more energy.

Control Unit Cabin

Container Monitoring Unit

As the highest-level control unit in the Smart String ESS BMS, the CMU is critical to the safe operation of batteries.

Huawei BMS is divided into three levels from bottom to top: BMU (Battery Monitoring Unit), BCU (Battery Control Unit) and Container Monitoring Unit (CMU).

The CMU analyses and calculates the uploaded data, processes alarms, and stores records to implement SOC and SOH management between battery racks. In addition, the CMU collects information about the environment monitoring system of the energy storage system, implements comprehensive fire warnings, protections, and provides reliable fire safety assurance for effective prevention and protection.

Smart PCS

DC LV Panel

Each PCS DC input is connected to a branch in the DC LV Panel. The DC LV Panel has 14 circuit breakers for segment protection. The AC output is connected to the low-voltage side of the transformer and protected by the circuit breaker on the low-voltage side.

Smart Transformer Station

Optimal Cooling Solution

With the optimal cooling system, there is no active air exchange in Huawei Smart Transformer Stations, which helps to achieve higher availability and easier maintenance.

The hermetic separation enables the use in harsh environments. As no filters are used, maintenance is simple and fast.

Smart Transformer Station

Smart Design

Preconfigured with SmartCU, status, control, analog, and protection signals available to remote SCADA/Management system for easier operation & maintenance.

Smart Transformer Station

Simple Design

Prefabricated & pre-tested within 20' HC container. Easy transportation and no internal cabling work required onsite.

Smart Transformer Station

Active Safety

IAC type tested for higher safety.