We believe that integrating environmental,

health and safety considerations into our business practices is not only the right thing to do, but also good for our business.

Our commitment

SembCorp Industries recognises that in order for

us to be a truly successful company, we must behave

as a responsible corporate citizen and be committed

to improving the world around us. This commitment

shapes our present and future actions. We aim to

manage our impact on the environment, safeguard

the health and safety of our employees and contribute

to the communities in which we operate.

In line with this, we believe that integrating environmental, health and safety considerations

into our business practices is not only the right thing

to do, but also good for our business. It helps us to manage risk better, lower costs through improved efficiency, increase our value as an investment and

grow our business in an ethical and sustainable manner.

SembCorp Industries

Environment, Health and Safety (EHS) Statement

SembCorp Industries strives to be a leader – setting standards for the industry. We are committed to responsibly serving our community and safeguarding the environment. We aim to conduct all business operations in a manner that ensures the health and safety of our customers, employees, the communities

in which we operate and our ecological system.

Understanding the importance of health, safety

and the environment, we will:

- Assist the community by offering products, services and solutions that will better conserve and protect our environment

- Encourage conservation and recycling in an effort to increase participation in recycling and promote environmental awareness among our staff

and community

- Ensure safe operations, while minimising impacts

on the environment and the communities in which we operate

As part of our ongoing efforts to improve our operations in a responsible and environmentally sustainable manner, we will also:

- Comply with existing environmental health and safety laws and legislation in all our operations

- Continue research, development and employee training and education in order to conduct business in a responsible manner

- Conduct careful review of all procedures to improve performance and quality, with constant consideration of environmental factors

| SembCorp Group’s environmental business lines |

| Business |

Activities |

Countries of operation |

| |

| SembCorp Utilities (SembUtilities) |

Provision of natural gas, cogeneration of power and steam, power generation from natural gas and renewables, treatment of hazardous industrial waste, treatment and recycling of industrial wastewater |

Singapore, China, UK |

| |

| SembCorp Marine - JPL Industries |

Recycling of copper slag from shipyard grit-blasting |

Singapore |

| |

| SembCorp Environmental Management |

Operation of waste collection, recovery and sorting systems, medical waste incineration, paper recycling, construction waste recovery, biological waste treatment |

Singapore, Australia, China, India |

| |

| SembCorp Engineers and Constructors - Environmental Division |

Design and construction of wastewater collection and treatment systems,

building of waste management facilities |

Singapore |

| |

Translating this commitment into action is a significant undertaking, but we have made good progress in 2005. Implementation of ISO 14001 and other EHS management systems continued during the year. In addition, a number

of commendable safety, emission reduction and waste management initiatives were also launched across the Group. As a result we have managed to save resources, reduce our greenhouse gas emissions and make our workplaces safer.

2005 marked a significant year for our community involvement, with the launch of the Trailblazer-Wong Kok Siew Fund in aid of children, youth and education. Across the Group, SembCorp’s businesses also continued efforts to aid those in tsunami-stricken areas, offering our facilities as collection points for donations, collecting proceeds and donating cash, food, medicine and clothing. Our employees also volunteered their time, money and care to a number of community development initiatives.

As we move into 2006 and beyond, we aim to build on our efforts in the past year, address issues that are important to our stakeholders and become a more responsible and sustainable company.

Our approach

Our approach to incorporating environmental and social considerations into our business operations comprises four principles. Firstly, we actively invest in sustainable businesses that increase shareholder value. Secondly, we implement sound internationally recognised EHS management systems. Thirdly, we continually aim

to enhance the environmental safety and impacts on health of our processes, products and services through integrating EHS measures into our business processes,

as well as through ongoing feedback and innovation. Fourthly, we work closely with our partners and suppliers for mutual EHS improvement to effect a more far-reaching

positive impact.

Investing in sustainable businesses

With a view that environmental management issues

are opportunities for business and not just risks to

be managed, we have continued to invest in businesses

that have a positive effect on the environment.

(See table above for details of our environmental business lines.)

In 2005, the SembCorp Group continued to grow its environmental business lines. Significant milestones

and investments include:

- A £60 million (S$187 million) investment to build a new wood-burning power station at the Wilton International site, Teesside, UK. The plant will be one of the UK’s largest biomass renewable energy projects.

- The commencement of operation of the new 42 megawatt gas-fired turbine for SembCorp Utilities UK (SembUtilities UK) Wilton Power Station. The new unit, which replaces an existing oil-fired boiler, uses the latest “dry low NOx” technology, enhancing the efficiency of the plant and reducing the emission

of air pollutants.

- A US$8 million (S$13 million) investment in a joint venture company to acquire, expand, own and operate an existing 10,000 cubic metres per day integrated wastewater treatment facility in ZhangJiaGang Free Trade Zone in Jiangsu Province, China.

- The commencement of operations of a 12,500 cubic metres per day wastewater treatment facility in Nanjing Chemical Industrial Park, China.

- The commercial launch of Singapore’s first fleet of taxis running on compressed natural gas (CNG). The CNG was supplied by SembUtilities’ subsidiary SembCorp Gas, marking a milestone in green

fuel development in Singapore.

EHS management systems in place

Each business unit is responsible for managing its own EHS performance and initiatives. To this end, ISO 14001 has been well implemented throughout the Group, ensuring that proper environmental management systems

are put in place and regularly monitored. In addition,

a number of business units have gone beyond ISO 14001 certification by adopting complementary systems, specific to their business activities. When possible, we integrate our environmental, quality and safety measurement systems – achieving certification under ISO 9001,

ISO 14001 and Occupational Health & Safety OHSAS 18001. We also abide by CP 79, Singapore’s Code of Practice for Safety Management Systems for construction worksites.

(See table below for certification systems in place in our business units.)

Other proactive measures used by the Group’s operating units include SembCorp Marine (SembMarine) subsidiary Sembawang Shipyard’s adoption of Det Norske Veritas’ International Safety Rating System (ISRS). ISRS audits encompass 20 elements, including key EHS parameters such as accident investigation, emergency preparedness, materials and services management and planned inspections and maintenance. Sembawang Shipyard implemented ISRS in 1992 and has undergone yearly audits. In the 2005 audit, the yard maintained a rating

of Level 9 on a ten-level scale.

Embedding EHS measures in our operations

Our EHS management is strengthened through the embedding of EHS measures in our operational processes and the setting of key targets.

These embedded EHS measures can take the form

of controls put in place for products. An example of this

is SembCorp Engineers and Constructors (SembE&C)’s Total Environmental Quality Score system, which integrates environmental considerations into the

building design process. More than 50 criteria are applied to each SembE&C building project at the design stage.

If the project does not achieve a minimum score

(73 out of 100) it is sent back for review and re-design.

More often however, EHS measures are embedded in operational processes. For instance, Sembawang Shipyard has a host of in-house performance management systems including a Behaviour-based Safety Programme, an EHS Code of Conduct backed by fines for violations by workers and contractors, regular environmental audits and a red card / yellow card system for EHS violations. EHS data is also monitored and reviewed at a monthly Shipyard Industrial Safety & Health Committee meeting chaired

by the yard’s managing director, with an overall review

on an annual basis.

Meanwhile, SembCorp Logistics (SembLog) subsidiaries, ST-Airport Services and Singapore Offshore Petroleum Services, set a zero-target for accidents, injuries and spillages and practices “near-miss” and hazard reporting.

In addition to proper safety monitoring and management, SembCorp’s operations staff also undergo extensive safety training. For instance, SembUtilities staff and contractors undergo training in chemical safety, confined space entry, waste management, fire safety, first aid and hazardous material spill control. In addition, emergency drills

and exercises are also regularly carried out to test emergency preparedness.

At SembE&C, each individual project conducts its own safety promotion activities such as job safety and hazard training, involving all levels of employees from line workers to senior managers.

Audits are also incorporated into our operations to strengthen the functioning of EHS management systems. For instance, SembUtilities identifies key strategic issues for the company such as greenhouse gas emissions and carries out annual environmental and risk assessments

at applicable facilities.

Engaging employees

To drive staff commitment and build an organisation-wide safety culture, employees are assessed on their EHS performance. For example, SembLog and SembE&C have a balance scorecard of EHS metrics to track and evaluate the performance of site employees and senior managers. Similarly, SembCorp Environmental Management (SembEnviro) promotes a “zero-accident” policy for all its vehicle operations. Operations staff who achieve this are recognised through in-house awards in addition to awards endorsed by the National Safety Council of Singapore.

SembCorp Industries also actively encourages staff at all levels to contribute ideas and suggestions from an operational perspective to improve workplace practices and products and services, including their environmental safety and impact on employee health.

Innovation and quality circles at SembUtilities, SembE&C, SembLog, SembCorp Parks Management, Batamindo Investment Cakrawala and Bintan Inti Industrial Estate, comprising cross-functional teams, provide a dynamic platform for sharing ideas and suggestions.

On a Group-wide level, outstanding solutions are also rewarded at our annual intra-Group Innovate, Discover, Engineer and Achieve (IDEA) Awards. Award-winning entries in 2005 included the recycling of industrial wastewater into highly purified water for industrial use;

an innovative device for reducing injuries while shifting and aligning pipes; and a scheme for the utilisation of

heat inertia from tripped boilers to continuously supply steam to customers without any interruption in the event of a trip at our Jurong Island cogeneration plant.

We also encourage employees to participate in national awards for EHS, leveraging on these to affirm the value of staff EHS contributions. In 2005, Sembawang Shipyard received the Ergonomic Solution Award from the Ministry of Manpower for ergonomic and safe solutions employed at the workplace for all employees. The shipyard also clinched silver and bronze awards at the Safety Innovation Team Convention for its innovative ideas for safe use

of cable cranes and hull hooks.

Working with our partners

We understand the importance of working closely

with our clients, contractors and suppliers to manage

the environmental and health impacts of our core

business operations.

For instance, EHS accountability to customers is encompassed in Sembawang Shipyard’s alliance partnerships with long-term customers such as Shell

and BP. For work on vessels commissioned by these alliance partners, EHS performance is monitored on a per-ship basis and the data is presented to the alliance partner during the yard’s Annual Alliance Review.

Sembawang Shipyard’s Contractor of the Month award is another example of working with contractors to improve the safety of processes and work environments. The EHS performance of the contractor is the main criteria for selection of the award; half the cash prize of S$10,000 must be used by the contractor to purchase personal protective equipment for its workers.

Both SembE&C and SembLog also include EHS criteria in their comprehensive vendor and partner selection systems. SembE&C’s Partner of Choice scheme gives preference to vendors and sub-contractors who qualify under these criteria, offers a premium price to them and waives any performance bond. Meanwhile, SembLog’s Core Vendor Selection Criteria screens vendors by certification in ISO 14001 and OHSAS 18001.

In addition to training its own employees in safety management, SembE&C also trains its sub-contractors to bring them on board to its zero-accident safety vision. Vendors and contractors are also invited to participate in seminars and training courses to ensure better understanding and adoption of the company’s EHS policies.

Our initiatives

The following sections focus on SembCorp Industries’ significant environmental, health, safety and social initiatives undertaken in 2005.

Energy conservation and clean air

In 2005, SembUtilities Singapore successfully converted

all of its boilers on Jurong Island from heavy fuel oil

to natural gas. With this, the steam and power that we

supply to customers in Singapore is now sourced entirely from a fuel that generates substantially less air emissions and no waste, compared to fossil fuels. In addition, the minimum turndown temperature of the boilers was lowered as a result, causing boiler efficiency to increase

to 93.5%. Our customers also stand to enjoy cost savings of approximately S$15 million per year, based on the price of fuel oil in 2005.

At SembUtilities UK, we continued to supply our customers with steam and power produced from

tallow, a form of renewable fuel. In 2005, we burnt

approximately 78,000 tonnes of tallow (70,050 tonnes fuel oil equivalent). The project has been recognised as contributing towards the UK’s goal of producing 20% of

its energy from renewable sources by 2010.

SembUtilities UK furthered its foray into renewable

energy by investing £60 million (S$187 million) in a

new wood-burning biomass power station, Wilton 10. Construction for this project began in October 2005.

This pioneering facility is set to become one of the UK’s largest biomass renewable energy projects, generating

30 megawatts of electricity. “Biomass” refers to renewable plant-derived organic matter – such as dedicated energy crops, trees and wood wastes – used in place of fossil fuels to generate energy or energy-related products. Wilton 10 will be fuelled by discarded wood from sawmills and forestry operations, as well as from specially grown energy crops cultivated within a 50 mile radius of the site. The cultivation of these energy crops will in itself mean the afforestation of 7,500 acres, the equivalent of around 3,000 football pitches, and will create wildlife havens throughout the region.

SembLog minimised its vehicular air emissions by purchasing three 40,000 litre mobile refuelling units

for its transportation vehicles. The capacity is three times that of SembLog’s current transportation vehicles and will cut down the number of refuelling trips made, thereby reducing emissions.

Sembawang Shipyard also achieved its goal of phasing out all ozone depleting substances from its fire-fighting systems in 2005 by converting to hydrochloroflurocarbon-based (HCFC-based) systems instead of the more destructive halon-based fire extinguishers.

Water

In 2005, SembUtilities continued its development

of an ongoing industrial effluent recovery project on Jurong Island that aims to reclaim 52% of industrial effluent as demineralised water and to conserve Singapore’s precious water resource. Approximately

6,240 cubic metres per day of industrial effluent is passed through a series of physical, chemical and biological treatment processes every day, removing all biodegradable components, which are then discharged safely.

To further our water conservation measures, rainwater is collected by SembLog in purpose-built tanks at two logistics centres for non-potable uses such as toilet flushing and cleaning. In addition, seawater is used to cool the air-conditioning system at one of our logistics centres. These measures have reduced our demand for processed water and led to significant cost savings.

Waste management and resources

In 2005, Sembawang Shipyard achieved a cost recovery of approximately S$5 million from its Waste Management Programme, which aims to reduce materials wastage and increase recycling. The programme involves waste segregation and recovery of materials from paint drums, zinc anoldes, ferrous and non-ferrous metals.

Similarly, by making simple changes to our packaging practices, we managed to substantially reduce our materials usage and costs. SembLog reduced its materials use by standardising the sizes of packaging and storage materials such as containers, trays and pallets, as well as fabricating them in durable plastic.

As an enhancement to its waste collection services and to boost recycling, SembEnviro invested in dual-compartment waste collection trucks in 2005. Equipped with separate compartments that can store both waste and recyclables, these trucks enable daily recycling at residential facilities and help to minimise waste in Singapore.

Health and safety

During the outbreak of dengue fever in October 2005, SembE&C worked with the Building Construction and Timber Industries Employees’ Union representatives

to visit work sites and teach workers dengue prevention techniques. Major work sites also established their own in-house pest control teams and worked in tandem with licensed pest control operators to prevent mosquito breeding. In addition, SembE&C appointed designated factory doctors for all construction sites and a resident industrial nurse at selected sites, to provide first aid and mitigate injury risk. With such robust safety measures in place, SembE&C received a Silver Award and nine Certificates of Merit under the Ministry of Manpower’s 2005 Annual Safety Performance Awards.

SembUtilities UK received recognition for its health and safety excellence in September 2005. It was jointly awarded the British Safety Council’s prestigious Sword of Honour award, together with six other major companies located at the Wilton International industrial site. The Sword, which recognises competence in managing health and safety risks and success in promoting an organisation-wide safety culture, is widely regarded as the global pinnacle of workplace health and safety achievement. SembUtilities UK and its six other co-applicants not only achieved the award at the first attempt, but also collectively became the first multi-company site to gain the award since its inception 26 years ago.

Nature conservation and environmental awareness

In 2005, Sembawang Shipyard continued its long-term sponsorship of the annual Green Wave Environmental Care Competition for schools. The competition, which aims to promote awareness and a sense of personal responsibility for the environment amongst students,

as well as encourage creative thinking for environmental improvement, attracted more than 1,000 participants in 2005. Students’ projects covered a wide array of environmental concerns. Some 43 awards, including

prizes of up to S$10,000, were given out.

SembEnviro organised a Recycling Day at a local constituency to facilitate recycling efforts and build awareness within the community. As an incentive for participation, it offered to exchange recyclables for household essentials such as rice, instant noodles and tissue packs. A total of 13 tonnes of recyclables were collected during the event.

Community involvement

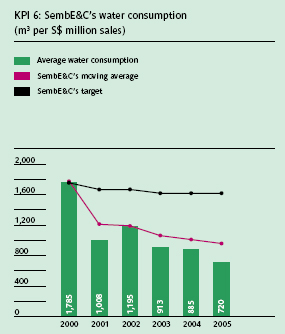

In 2005, the SembCorp Group continued to support charitable, educational and cultural causes through

direct donations and in-kind support. (See KPI 1: SembCorp Group’s charitable giving & community on page 121).

In July 2005, SembCorp Industries and its subsidiaries launched the S$1.2 million Trailblazer-Wong Kok Siew Fund, consolidating community giving efforts across the Group and building on the Group’s community focus on children, youth and education. Pooling its resources and efforts under the Fund enables the Group to adopt a better coordinated and holistic approach to its charitable efforts and provides a focal point to galvanise greater support and attract donations from outside the

SembCorp Group.

Key programmes under the fund include the following:

- School Book Assistance Grant (SchoolBAG) by SembMarine to assist low-income households with school children in purchasing textbooks, uniforms and stationery at the commencement of the school year.

- Global Learning Journey by Singapore Mint to educate school children about foreign countries in a creative way, using coins, educational exchanges

and visits to foreign mints.

- Jamiyah Children’s Home sponsorship by SembEnviro to support 77 less privileged children.

In 2005, the Group also continued in its efforts to help people in tsunami-stricken areas. SembEnviro raised S$11,682 and collected over 16 tonnes of clothing,

whilst SembE&C donated S$17,260 and containers full

of clothing, medication, dried food and drinking water

to the Singapore Red Cross Society’s disaster relief efforts.

In addition, SembLog opened up two of its logistics centres as collection points for public donations

and was awarded a commendation from the National Volunteer and Philanthropic Council for ‘Significant Contributions to the Relief and Reconstruction Efforts after the Asian Tsunami Disaster’. SembCorp Parks Management’s (SembParks) PT Bintan Inti Industrial Estate and its tenant, PT Tunaskarya, jointly carried out a donation drive in aid of tsunami victims in Aceh and North Sumatra.

Our employees also volunteered their time to the community in various ways. For example, SembLog volunteers helped to sort and pack food and gift

items for the needy as part of the Boys’ Brigade Sharity Gift Box scheme. During the dengue fever outbreak in Singapore, 11 SembEnviro employees volunteered to participate in the National Environment Agency’s “carpet-combing” exercise for dengue fever prevention in the community.

Our contributions also extended to communities in Vietnam and Indonesia, where SembParks operates its industrial parks. Batamindo Industrial Park (BIP) sponsored scholarships to 605 students from the nearby community worth S$36,075, whilst the Vietnam-Singapore Industrial Park (VSIP) sponsored scholarships for 40 students totalling S$30,000. In addition, BIP also donated food and medical aid worth S$33,483 to needy recipients in its community, whilst VSIP donated S$5,000 to the Vietnam Red Cross.

Our performance

In addition to the key initiatives above, in 2005 we continued to monitor our environmental, safety and community performance quantitatively through the use of Key Performance Indicators (KPIs). Due to the diverse nature of our operations, separate KPIs specific to each

of our five main business units were applied, in addition to a Group-wide KPI for charitable giving. Our scorecards are presented on pages 121 to 123.

KPI 1: SembCorp Industries –

Charitable giving & community

The total amount of charitable donations by the

SembCorp Group in 2005 was S$2.3 million, compared with S$1.1 million in 2004. Through these donations we actively support charities, philanthropic efforts, educational events, welfare groups, community events

and underprivileged people.

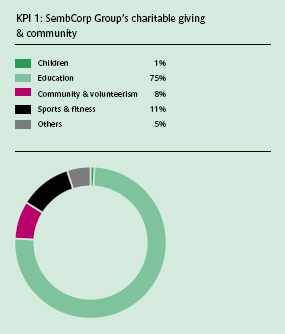

KPI 2: SembUtilities – CO² Emissions

KPI 2: SembUtilities – CO² Emissions

Carbon dioxide (CO

²) from SembUtilities’ worldwide power generation activities is one of our major remaining emissions and hence is one of our KPI. We have achieved good reduction in CO

² emissions per million dollar sales over the last few years. In 2005, we continued to reduce our emissions by using natural gas in place of fuel oil in selected boilers and by obtaining energy from renewables.

KPI 3: SembMarine’s Sembawang Shipyard – Accident frequency rate

KPI 3: SembMarine’s Sembawang Shipyard – Accident frequency rate

Safety has always been a key priority of SembMarine’s shipyards. Our Environment, Health and Safety

Management System at Sembawang Shipyard has been in place since the 1970s and a Behavior Based Safety system, since 2001. We are profiling the accident frequency rate

as the KPI for Sembawang Shipyard.

KPI 4: SembLog’s ST-Airport Services – Fuel spillages

ST-Airport Services’ core business includes the transport, storage and delivery of large quantities of aviation fuel. Product spillage can cause water and ground contamination, increase fire risk and result in other negative impacts. To minimise this risk, we have put in place a comprehensive management system consisting

of procedures and monitoring programmes to prevent fuel spillage. Hence we are profiling fuel spillages as the KPI for these operations. We have achieved our target of zero spills every year since beginning operations in 1996.

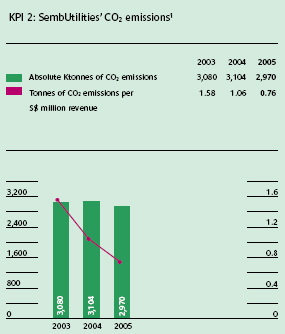

KPI 5: SembEnviro – Vehicle accident rate

With a fleet of more than 300 vehicles on the road 365 days a year, road safety is of utmost importance to SembEnviro. We have been monitoring our vehicle accident rate KPI closely and have put in place a number of initiatives to reduce accidents. Our efforts to improve safety have led to a drop in the accident-to-kilometre (km) travelled ratio to 0.68 accidents to every 100,000 km travelled in 2005, well within our target of less than one accident per 100,000 km.

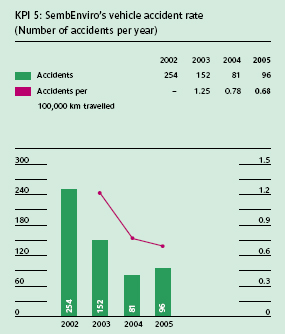

KPI 6: SembE&C – Water consumption

KPI 6: SembE&C – Water consumption

Reducing the consumption of water, a precious

resource in Singapore, has been an integral part of

our environmental management system for many years. SembE&C continued to reduce its water consumption per million dollar of sales in 2005 and remains committed to reducing the amount of water utilised for our construction activities and processes.