|

|

|

|

|

| |

|

| |

Sembcorp’s priority is to deliver long-term value

and sustainable returns to our shareholders. As a

multinational enterprise and a public listed company,

we understand that there is a complex value chain

to which Sembcorp belongs and that our wider

responsibility incorporates sustainability issues. We

fully recognise that these issues may be outside the

traditional view of corporate activity, but as the

global business landscape evolves, managing these

issues is increasingly viewed as vital in maintaining

a company’s ’licence to operate’ from society and

their stakeholders.

This widening role of business is taken seriously and

is reflected in Sembcorp’s commitment to excellence and

continuous improvement. In our management approach

to sustainability and governance, many issues are directly

addressed at the Group level with the support and

input of the business units. Our management of

material issues of health, safety and environmental (HSE)

performance as well as corporate governance and risk

management and mitigation contributes to enhancing

and preserving the value of our business. In addition,

we continue to maintain an ongoing commitment to

community investment initiatives.

With customers and operations around the world,

Sembcorp is an international company. Our three

main operating units comprise our Utilities business

(which now includes the solid waste management

business), as well as our Marine and Industrial Parks

businesses. As our Marine business is separately listed

in Singapore and reports its activities in a separate

annual report, this report will primarily cover the other

two business units (BUs). Data for key performance

indicators for these BUs has been tracked and reported

in the areas of environment, health and safety, human

resources and community investment. Aside from this chapter, information on the company’s corporate

governance, risk management and mitigation

strategies, and investor relations which are part of the

wider ambit of sustainability issues, may be found in

the relevant chapters under the Environmental, Social &

Governance (ESG) Review section of this annual report.

The following sustainability report addresses the

activities and data that fall within the company’s

financial year for the period from January 1 to

December 31, 2010. Sembcorp has included aspects

of sustainability in our annual report since 2001, and

sustainability issues were last reported in our annual

report for the financial year 2009 published in 2010,

which applied the Global Reporting Initiative (GRI) G3

reporting principles and framework and aspects of the

GRI Electric Utility Sector Supplement on a voluntary

basis. Sembcorp was one of the first companies listed

on the Singapore Stock Exchange (SGX) to publish

a voluntary sustainability report using the GRI G3

guidelines as a reporting framework. This year, we

have continued to use the reporting principles and

framework for the GRI G3 and considered the principles

of the GRI in terms of materiality, stakeholder

inclusiveness, sustainability context, completeness,

accuracy and comparability.

Our aim is to work towards providing readers

with an accurate, complete and reliable report

that contains meaningful information on how we

manage sustainability issues in our specific business

sectors. We have tried to incorporate as much data as

possible from our ongoing operations and the scope

of this report includes reporting on our majority

owned business units, particularly our operations in

Singapore and the UK. This year, we have been able

to include some additional information from our

Utilities operations in China, Vietnam and the UAE.

In 2010, Sembcorp acquired a 97.66% stake in Cascal,

a provider of water services to the municipal market

with operations in China, Indonesia, Philippines, South Africa, the UK, the Caribbean, Chile and Panama.

The data presented in this report excludes our newly

acquired operations under Cascal as well as Shanghai

Cao Jing Co-generation in China where we hold a

minority stake. Where data is unavailable or has

been excluded, this has been clearly stated, and data

measurement is in line with GRI G3 recommendations

for our chosen indicators. Sembcorp is committed to

continuous improvement and aims to expand the scope

of the report in the future. Our target for our ongoing

reporting development is to incorporate reporting on

BUs in which Sembcorp has a majority stake. Our aim is to work towards providing readers

with an accurate, complete and reliable report

that contains meaningful information on how we

manage sustainability issues in our specific business

sectors. We have tried to incorporate as much data as

possible from our ongoing operations and the scope

of this report includes reporting on our majority

owned business units, particularly our operations in

Singapore and the UK. This year, we have been able

to include some additional information from our

Utilities operations in China, Vietnam and the UAE.

In 2010, Sembcorp acquired a 97.66% stake in Cascal,

a provider of water services to the municipal market

with operations in China, Indonesia, Philippines, South Africa, the UK, the Caribbean, Chile and Panama.

The data presented in this report excludes our newly

acquired operations under Cascal as well as Shanghai

Cao Jing Co-generation in China where we hold a

minority stake. Where data is unavailable or has

been excluded, this has been clearly stated, and data

measurement is in line with GRI G3 recommendations

for our chosen indicators. Sembcorp is committed to

continuous improvement and aims to expand the scope

of the report in the future. Our target for our ongoing

reporting development is to incorporate reporting on

BUs in which Sembcorp has a majority stake.

Issues that are material to Sembcorp and its

stakeholders are reviewed on an ongoing basis as the

company continues to expand in terms of size and

geography. In general, Sembcorp’s management and

monitoring of sustainability issues is based on a risk

management approach. We have also identified the

AA1000 five-part materiality test as a useful tool to

identify material areas to address and have begun

using feedback obtained through a pilot stakeholder

survey in line with AA1000 to better understand the

Group’s sustainability risk profile.

In addition, we recognise that there are tremendous

opportunities to actively invest in sustainable business

lines. Using our integrated group strength, we apply

proven technologies to produce energy in greener ways,

create innovative solutions for clean, sustainable water

and help manage resources through the treatment and

recovery of recyclables from waste. In this way, we not

only do our part to limit the impact of our activities on

the environment while staying competitive, but also

help our customers to do the same.

At Sembcorp, we recognise the importance of being

an active player within our industry and engaging with our peers and the wider business community on

sustainability issues. Sembcorp is a founding member

and supporter of the Singapore Compact for Corporate

Social Responsibility, a national society promoting

sustainability issues in Singapore.

At the industry level, Sembcorp participates in

the Responsible Care voluntary initiative, endorsed

in Singapore by the Singapore Chemical Industry

Council. This encourages members to adopt 10

guiding principles for a safer chemical industry

through the six management practices of employee

health and safety, distribution, pollution prevention,

process safety, product stewardship and community

awareness and emergency response. In Singapore,

Sembcorp is also a member of the Sakra Island

Community Awareness Group, which seeks to

promote community awareness and a standardised

management practice code for emergency responses

among companies located in the Sakra district on

Singapore’s Jurong Island. Similarly, our Teesside UK

operations are also active in the Northeast England

Process Industry Cluster which serves as a unified voice

for the process industry in northeast England, where

a substantial part of the UK’s chemical, petrochemical,

speciality chemical, pharmaceutical, polymer and

biotechnology industries are based. In the UAE,

our operations in Fujairah participated in the Abu

Dhabi Water and Electricity Authority’s task force in

formulating HSE procedures and guidelines for the

energy sector.

Our internal stakeholders are also crucial in our

day-to-day practice of sustainability and in determining

our sustainability-related risks and identifying areas

for future improvement. As part of our efforts to

create a culture of open, two-way communication,

employees are encouraged to contribute ideas on

improving workplace practices and the delivery of

products and services. This includes feedback on issues

such as dishonesty and fraud via our whistle-blowing

scheme and confidential feedback channels. To

further promote sustainability as a part of Sembcorp’s

corporate culture, employee appraisals take into

account HSE performance.

Sembcorp’s supply chain is a complex one and our

actions influence both our own businesses and others

along the value chains we operate in. Many of our multinational clients are in the process of developing

and integrating their own sustainability programmes

and Sembcorp aims to be a key provider in assisting

them to improve their HSE performance, limit their

environmental impact and conserve resources.

As a provider of utilities, Sembcorp directly

consumes primary resources, produces waste and

emissions and manages and maintains buildings,

people, treatment processes and machinery. As a result,

we must work closely with our suppliers, business

partners and contractors to promote sustainability.

Our commitment to aspects such as HSE performance,

pollution control at source and waste management,

ensures that our policies and practices deliver wider

benefits to relevant stakeholders groups. For example,

Sembcorp assesses general contractor capability to

ensure that projects carried out are in line with our

HSE policy. Through platforms such as contractor HSE committee meetings, safety induction programmes

as well as vendor performance audits, we also

work alongside suppliers to actively identify and

improve performance.

Our company’s main stakeholder groups have

been identified as regulators, financial institutions,

shareholders and the investment community,

suppliers, customers, members of communities where

we have operations as well as our employees. To

better understand our internal and external business

environment, Sembcorp actively engages with

its stakeholders.

Between 2009 and 2010, we carried out a pilot

stakeholder engagement project applying the AA1000

Stakeholder Engagement Standard to seek the views

of stakeholder groups such as investors, customers, suppliers and employees, as well as a Singapore non-governmental

organisations, to better understand

their expectations for Sembcorp’s practice of

sustainability. Questionnaires and telephone interviews

were used to gather data and to ensure neutrality

and openness in the engagement process, external

consultants were appointed to undertake the project

and report on its findings.

The top issues which internal stakeholders felt

were important were health and safety, corporate

governance, labour rights and continued development

of green business lines. A need for training to further

enhance knowledge in the sustainability domain was

also identified. There was also a consensus amongst

external stakeholders that Sembcorp’s reputation for

sustainable practices and sustainability reporting is

important. HSE performance and compliance with

regulatory requirements were high priorities. Suppliers

highlighted the importance of working collaboratively

to anticipate and comply with future regulations,

achieve efficiency in energy and water usage, and

reduce the carbon footprint of our operations.

Investors identified a number of issues important

for companies’ sustainability in general and also

specifically for Sembcorp. These included identification

of material issues, ESG targets and performance in

identified areas, and the use of external guidelines

such as GRI guidelines, amongst others.

Through this and other formal engagement

processes, we aim to continue to align relevant

stakeholder issues with our overall strategy.

In line with our continual drive for innovation

and to widen our sustainable business portfolio, the

development of sustainable or ’green’ business lines

has become a growing part of our ongoing businesses.

We foresee sustainable products and services delivering

an additional competitive edge and enhancing our

reputation as a responsible and responsive company.

Sembcorp’s sustainable business operations include:

Sembcorp runs a 35 megawatt power station that

uses sustainable wood for fuel, the Sembcorp Biomass

Power Station, as a core part of its energy operations

at the Wilton International site in Teesside, UK. The

plant was the first large-scale wood-fired renewable energy plant in the country. To further improve

efficiency of the station, work is underway on a

S$10 million (£5 million) modification to convert

the facility into a combined heat and power facility,

which will make the power station even more

environmentally friendly.

Sembcorp was Singapore’s first commercial importer

and retailer of natural gas, considered the cleanest of

all fossil fuels. We import 341 billion British thermal

units of natural gas per day from West Natuna in

Indonesia and supply major power generation and

petrochemical companies. Starting in late 2011, we

will import an additional 90 billion British thermal

units of gas per day.

Sembcorp aims to apply technology to achieve

greater efficiency and lower emissions in our power,

steam and desalination operations. A summary of

our use of such technologies may be seen in the

table below.

In May 2010, Sembcorp announced a joint venture

agreement with Gayatri Energy Ventures to build,

own and operate a 1,320 megawatt coal-fired power

plant in Krishnapatnam, India. While the plant will

be fired by coal, it will utilise supercritical technology

which reduces emissions of carbon dioxide and other

pollutants by consuming less fuel per unit of electricity

generated, reducing its associated environmental

impacts. Sembcorp expects the power plant to be

70% fuelled by low sulphur non-coking coal sourced

from within India.

Through Sembcorp’s range of services, waste

that would usually be disposed of in landfill and

incineration facilities is diverted for recycling. We also

have capabilities in advanced waste treatment and

resource recovery, including composting and waste-to-energy

recovery. In Australia, Sembcorp’s solid waste

management arm, SITA Environmental Solutions, is a

leader in the development and operation of advanced

resource recovery facilities.

Our waste-to-resource facilities in Singapore

extract recyclables from waste collected through our

municipal waste collection arm, which is the leading

operator in Singapore, serving four out of the nation’s

nine municipal sectors. Sembcorp also operates a

construction and demolition materials recovery facility

in Singapore capable of processing 300,000 tonnes of

construction and demolition waste per year. Timber,

hardcore and fines, as well as ferrous and non-ferrous

metals are recovered during the sorting process.

Furthermore, the complete range of waste paper

recycling services is offered from collection, sorting

and baling to bulk supply of recovered paper to

paper manufacturers. With more than 20 years of

experience in waste paper recycling, we have an

extensive network collecting some 300 tonnes of

waste paper each day.

Sembcorp is a pioneer in industrial wastewater

treatment and water reclamation in Singapore and

China. Our industrial wastewater facilities in China

and Singapore are capable of treating wastewater

up to 20 times more concentrated than municipal

sewage and up to 1.5 times more saline than seawater,

and help to limit the impact of industries on the

environment by treating their effluent to meet

environmental limits.

In 2010, Sembcorp successfully expanded our high concentration industrial wastewater treatment

business with the completion of a second plant in

China capable of treating concentrated industrial

wastewater from source, located at the Nanjing

Chemical Industrial Park. The new facility is capable

of treating up to 12,500 cubic metres of effluent per

day without customers having to pre-treat it first. This

saves customers the need to invest in pre-treatment

facilities for their wastewater, and at the same

time, also supports local authorities in their goal of

environmental protection. Meanwhile, in Singapore,

we announced the upcoming development of a new

integrated wastewater treatment plant to serve

growing customer needs in the newly developed area

of the Jurong Island petrochemical manufacturing

cluster. Capable of treating multiple streams of

complex industrial wastewater, the plant will more

than double the current industrial wastewater

treatment capacity on Jurong Island with its initial

capacity of 9,600 cubic metres per day.

Beyond treating wastewater, Sembcorp also reclaims

water from treated effluent, conserving precious

water resources and offering a sustainably-sourced

alternative water supply to industries and households.

In Singapore, the company was the first company to

reclaim secondary effluents from wastewater, applying

dual-media filtration, microfiltration, reverse osmosis

and ion exchange technologies to produce high purity

demineralised water and high grade industrial water for supply to its customers. Today, Sembcorp’s supply

of demineralised water and high grade industrial

water to customers in Singapore is substantially

derived from reclaimed water. Our ability to integrate

wastewater treatment, water reclamation and water

supply in a ’closed loop’ minimises liquid discharge,

conserves potable water supplies and promotes a

sustainable water supply.

In 2010, Sembcorp officially opened its Sembcorp

NEWater plant, one of the largest water recycling

plants in the world, with a capacity of 228,000 cubic

metres per day. The plant’s completion marked a

major step in Singapore’s water sustainability journey.

It is one of the few water reuse plants in the world

to be built on top of another water reclamation

treatment plant, minimising its plant footprint in

a land-scarce country. The facility’s state-of-the-art

microfiltration and reverse osmosis systems are also

designed for optimum energy consumption.

Sembcorp’s Industrial Parks business applies an

integrated approach to township development,

providing world-class manufacturing space coupled with

an environmentally sensitive approach to development.

In January 2010, we held a groundbreaking

ceremony for our fourth Vietnam Singapore

Industrial Park (VSIP) development in Hai Phong,

Vietnam. Integrating conservation considerations in

its masterplan, 30% of land within the development

is reserved for green space and the preservation of

local flora and fauna. Existing wetlands on the site

as well as tributaries from the Cam River that run

through the township will be preserved and made a

feature of the development. Vietnam, with its growing

trend of urban migration, requires sustainable urban

solutions. With its environmentally sensitive approach

to development, VSIP Hai Phong has potential to be

a showcase of such sustainable urban development in

the country.

In 2010, we also completed the conceptual

masterplan for the 1,500 hectare Sino-Singapore

Nanjing Eco High-tech Island (SNEI) in China’s Jiangsu

province. Leveraging on the central government’s

long term goal of creating a sustainable economy

with environmental preservation, 870 hectares of

the SNEI’s gross land area will be preserved for eco-tourism.

The remaining 630 hectare development

area will feature eco-friendly residential designs

and knowledge industry development. The SNEI is

envisioned to render the Jiangxinzhou island on

which it resides as a model for sustainable growth

characterised by eco-styled urbanisation.

Research and development plays an important

role in strengthening Sembcorp’s sustainable

capabilities. As a business, our continued drive for

technology and innovation allows us to optimise

existing facilities and processes and use energy

more efficiently. This means better use of resources,

lower costs, better safety performance and reduced

environmental impact.

Sembcorp’s operations are supported by our in-house

Technology department, as well as the collective

expertise of our entire Group. In addition, in 2010,

we also set up a Group Technology Committee that is

headed by Sembcorp’s Chairman and Group President

& CEO. We also form research arrangements and

collaborations with local tertiary research institutes

and water technology companies. An example of

such a partnership is our ongoing collaboration

with Nanyang Technological University’s Nanyang

Environment and Water Research Institute, to jointly

explore new technology to remove recalcitrant organic

materials from complex industrial wastewater. Pulling

together these extensive intellectual resources, our

continued push for technology and innovation helps

to build our competitive advantage and support the

sustainable growth of the Group.

In 2010, Sembcorp received both national and

global recognition and a number of awards for its

efforts to promote and practise sustainability.

The Sembcorp NEWater Plant was recognised

for its contribution to the international water reuse

industry, winning the 2010 Global Water Awards Water

Reuse Project of the Year, as well as the WateReuse

Association’s WateReuse International Award. One of

the largest water reuse plants in the world, the plant

uses state-of-the-art technology to optimise land

use, has a compact plant footprint and strengthens

Singapore’s supply of NEWater, an ultra-clean, high-grade

reclaimed water which is a key pillar of the

country’s water sustainability strategy.

Sembcorp received Responsible Care Achievement

Awards from the Singapore Chemical Industry Council

in 2010 for Responsible Care’s Employee Health &

Safety, Pollution Prevention and Process Safety codes.

The awards honour companies which incorporate

Responsible Care Management Practices in their

operations, and maintain high health, safety and

environmental standards.

Sembcorp was ranked Singapore’s Most Transparent

Company in the multi-industry / conglomerates

category at the Securities Investors Association

(Singapore) Investors’ Choice Awards. The awards

recognise companies that adopt good corporate

governance practices through their efforts towards

excellent financial reporting and extensive disclosure

of information.

The bizSAFE programme, initiated by the Workplace

Safety and Health Council in Singapore, promotes

workplace safety and health through recognition

of companies’ safety efforts. Sembcorp Cogen and

Sembcorp’s Singapore solid waste management unit

achieved the highest level, or ’star’ status in 2010.

Sembcorp won three silver awards at the Singapore

Workplace Safety and Health Performance Awards

2010. The annual awards are presented to organisations

that have performed well by implementing sound

health and safety management systems. The three silver

awards were received by Sembcorp Gas, Sembcorp

Cogen and our propylene purification operations.

Sembcorp’s solid waste management subsidiary

SembWaste clinched Singapore’s top Total Defence

Award, the Minister for Defence Award, for its

outstanding contributions to total defence, especially

for its medical waste collection services during the

outbreak of Influenza A (H1N1) in Singapore in 2009.

The UK Water Services Regulation Authority (Ofwat)

ranked Sembcorp’s municipal water operations in

Bournemouth in UK, as the joint top performing water

company for service delivery in England and Wales,

maintaining the unit’s number one ranking for the

second year in a row. The company achieved its best

ever performance by scoring 288 points, the maximum

possible in the regulator’s assessment of the overall

quality of service, including reliability and continuity of

water supply, drinking water quality, and management

of leakage provided by water companies.

Sembcorp’s operations in Teesside in UK were

honoured twice at the prestigious UK National Training

Awards 2010. The vastly experienced Protection

Team won both a Regional and National Training

Award in recognition of Sembcorp’s outstanding

contribution and commitment to training, learning

and development in the workplace. Sembcorp was

the first in UK to put its entire industrial fire-fighting

force of almost 100 site protection officers through a

new Level 3 National Vocational Qualification designed

specifically for professionals in the fire-fighting and

rescue sector.

In 2010, Sembcorp’s VSIP was presented a Saigon

Times Top 40 Award by The Saigon Times and the local Department of Planning and Investment. This prestigious

award recognised the best performing foreign direct

investment enterprises and their efforts towards

environmental conservation and sustainability, as well as

their contributions to the economy and community.

VSIP’s efforts have been endorsed by the Vietnam

Association for Conservation of Nature and Environment,

who awarded VSIP with its Greentech Certificate

in recognition of its proactive efforts in managing

environmental issues and implementing measures for

environmental sustainability.

Our operations in Mbombela, South Africa, were

amongst the only 5% of the country’s water networks

to be given ’Blue Drop’ status by the Department of

Environment and Water Affairs, in recognition of

their provision of high quality water services. The Blue

Drop scheme is meant to build public confidence in

the quality of the drinking water and to ensure that

proper monitoring measures are taken to ensure safe

drinking water.

HSE issues are clearly linked with Sembcorp’s long-term

success, and have been identified as material

factors in terms of their potential impact on our

business operations, as reflected in feedback from

our stakeholder engagement survey. Expectations of

our key stakeholder groups continue to increase in

this area and our HSE performance is an important

component of assessment for the Group as a high

quality investment, business partner and supplier.

The Group HSE policy can be viewed on our website at

www.sembcorp.com. In managing our HSE issues, we

continue to be guided by four main principles:

| • |

Implementing internationally recognised HSE

management systems such as ISO 14001:2004

and OSHAS18001:2007. |

| • |

Actively investing in financially viable sustainable

business lines, which form part of our core operations. |

| • |

Pursuing continuous improvement to enhance HSE

performance of our processes, products and services. |

| • |

Working closely with our business partners and seeking active engagement to promote mutual HSE performance improvement and positive impacts. |

This section of the report provides information

on how the Group proactively manages HSE impacts

arising from its operations. It covers key issues

including clean air and climate change, water, waste

and the health and safety of our employees and

business partners.

This 2010 report includes data from not only

Singapore and the UK, which were the main focus

of the 2009 report, but also from operations in

Vietnam, the UAE and China (excluding newly acquired

operations from Cascal as well as Shanghai Cao Jing

Co-generation where we hold a minority stake). In the

case of some indicators, this broader scope of reporting

may mean that there is no meaningful comparable

year-on-year data.

With operations that spread across six continents,

our Group HSE department is the driver of our

management systems and co-ordinates our global

HSE efforts. Management committees and reporting

structures have been established with regional

co-ordinators working closely with the Group HSE

department. This ensures the effective management

of HSE issues with the purpose of setting long-term

HSE objectives and targets and complying with the

regulatory requirements, voluntary group guidelines,

standards and initiatives. From early 2011, HSE issues

have been incorporated into regular reports to the

board and key HSE risks and controls have also been

presented to the board’s Risk Committee.

In 2010, Sembcorp’s growth presented the challenge

of aligning HSE policies and standards throughout

the company, particularly in our newer operating

sites. Going forward, our priority continues to be on

aligning and improving standards across the Group and

proactively managing HSE throughout the entire asset

management life cycle, from business development

and project conception, through to operation until

end of the life of the asset.

The HSE culture at Sembcorp is one of shared

responsibility, involving everyone associated with the

company. With this approach, employees, business

partners and contractors take ownership of day-to-day

health, safety and environmental performance,

and meet expected standards. We continue to work

with our partners and suppliers towards mutual HSE

improvement. In Singapore, the Sembcorp Contractor

HSE Committee continues to promote co-operation

with our contractors in achieving and maintaining

HSE performance on Jurong Island.

As a key player in the energy sector, we are keenly

aware of global climate change issues. We aim to

limit and manage the impact of our operations on

climate change by enhancing our efficiency and

investing in assets applying technologies which manage

and reduce emissions.

Data shown in this section is from operations in

Singapore and Teesside in the UK unless otherwise stated.

Compilation of our emissions data is in accordance to the

World Resource Institute and World Business Council for

Sustainable Development’s Greenhouse Gas Protocol for

Stationary Combustion (Version 4).

In our Singapore and Teesside UK operations,

carbon dioxide emissions have remained at around

the same levels as in 2009 at around 2,330 kilotonnes

and 790 kilotonnes respectively.

In addition to carbon dioxide emissions, we have

begun to widen the scope of our data to include

other sources of emissions.

In 2009, due to a natural gas curtailment by our

suppliers, our Singapore operations substituted natural

gas with fuel oil and emitted 85 tonnes of oxides of

sulphur (SOx). SOx emissions have since decreased

by more than 60% to 30 tonnes in 2010. In Teesside,

UK, SOx emissions were also reduced by more than

40%, from 978 tonnes in 2009 to 564 tonnes in 2010.

Total emissions of oxides of nitrogen (NOx) for our

operations in Singapore and Teesside in UK in 2010

decreased by more than 50% as compared to 2009.

In Singapore, NOx emissions decreased by more than

70%, from 1,707 tonnes in 2009 to 461 tonnes in 2010

due to lower utilisation of boilers as a result of an

increase in the export of steam by our cogeneration

plant. In Teesside, UK, NOx emissions also reduced by

more than 20%, from 1,135 tonnes in 2009 to 859 tonnes in 2010. Reduction in SOx and NOx emissions

from operations in Teesside in the UK was due to the

lower utilisation of coal boilers during the year.

We continued to track our primary energy sources

usage in 2010. Natural gas continued to account

for the largest proportion of our fuels used. We also

continued to monitor indirect energy usage in the

form of electricity consumption by our operations within the scope of the report; this was over 2.3 million

gigajoules for 2010.

Our water business has grown significantly over

the last five years through acquisitions and organic

growth. We provide a range of services from

specialised industrial wastewater treatment to water

reclamation, desalination and the supply of potable

and industrial water. Sembcorp manages facilities

capable of producing and treating over six million

cubic metres of water and wastewater daily and

serves close to five million people worldwide. Through

innovation, we make every effort to ensure the

efficient use and reuse of water resources. the last five years through acquisitions and organic

growth. We provide a range of services from

specialised industrial wastewater treatment to water

reclamation, desalination and the supply of potable

and industrial water. Sembcorp manages facilities

capable of producing and treating over six million

cubic metres of water and wastewater daily and

serves close to five million people worldwide. Through

innovation, we make every effort to ensure the

efficient use and reuse of water resources.

As part of our water solutions to our customers,

we treat and supply water extracted from surface

water and groundwater (including lakes, rivers,

oceans and aquifers). In 2010 for our operations in

Singapore, Teesside in UK, China (excluding newly

acquired operations from Cascal as well as Shanghai

Cao Jing Co-generation), Vietnam and the UAE, we

extracted 815 million cubic metres of surface water

and groundwater, primarily for treatment and supply

to our customers and for use in our operations.

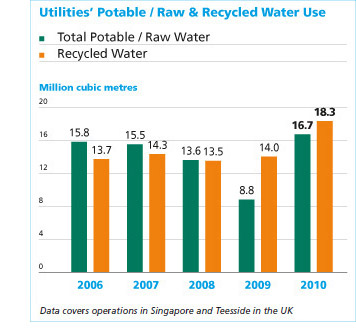

In 2010, our Teesside operations consumed over

16 million cubic metres of potable and raw water, including raw water consumption used to produce

demineralised water for our customers and for use

in our operations. Sembcorp also recycled 18 million

cubic metres of water for supply to our customers

and for use in our operations in Singapore and

Teesside in UK, reducing the need to draw on

potable or raw water supplies and also helping

our customers to reduce the amount of raw water

needed for their operations.

As one of the largest solid waste management

players in Singapore, Sembcorp provides services

that aim to reduce waste going to incineration or

landfill facilities. We also promote waste reduction

by encouraging recycling. In line with our business

focus to reduce waste for disposal, we are actively

developing differentiating know-how including

waste-to-resource capabilities.

In previous years we have reported on Sembcorp’s

internal SCU 5/0 campaign, which tracks the five goals

of zero injury, zero spill, zero non-compliance, zero

hazardous release and zero unplanned shutdown

and imputes a monetary cost to lapses (termed the

’price of non-conformance’) which is monitored over

time. This internal campaign was initially started

in Singapore for our Utilities operations and has

contributed to a substantial improvement in our

performance since its inception. As part of our efforts

to improve HSE performance across the Group we are

currently reviewing this to see how we can formulate

an enhanced standardised set of HSE reporting

parameters for application across all business units

both in Singapore and overseas.

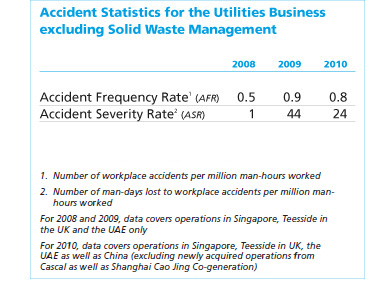

For 2010 we have been able to extend the scope of

our accident and injury rate reporting. Using indicators

of accident frequency rate (AFR) and accident

severity rate (ASR), in accordance with the tracking

criteria set by Singapore’s Ministry of Manpower, the

safety performance from our Utilities operations in

Singapore, UK, China and the UAE has been recorded

(China operations recorded data from February to

December 2010 only). In 2010 for the first time, we

have included data from our operations in China

(excluding newly acquired operations from Cascal as

well as Shanghai Cao Jing Co-generation) and the UAE. The solid waste management business’ safety

performance in Singapore is reported separately

from the performance of the rest of our Utilities

operations. This is due to the fact that the solid waste

management business’ waste collection operations

employ manual labour to a greater degree and

therefore have a different risk profile from our energy,

water and on-site logistics operations. For 2010 we have been able to extend the scope of

our accident and injury rate reporting. Using indicators

of accident frequency rate (AFR) and accident

severity rate (ASR), in accordance with the tracking

criteria set by Singapore’s Ministry of Manpower, the

safety performance from our Utilities operations in

Singapore, UK, China and the UAE has been recorded

(China operations recorded data from February to

December 2010 only). In 2010 for the first time, we

have included data from our operations in China

(excluding newly acquired operations from Cascal as

well as Shanghai Cao Jing Co-generation) and the UAE. The solid waste management business’ safety

performance in Singapore is reported separately

from the performance of the rest of our Utilities

operations. This is due to the fact that the solid waste

management business’ waste collection operations

employ manual labour to a greater degree and

therefore have a different risk profile from our energy,

water and on-site logistics operations.

Our Utilities operations excluding solid waste

management reported four accidents in 2010 – three

in the UK, including a case involving a contractor,

and one in China, with zero reportable accidents

in Singapore and the UAE. Our Utilities operations

reported 121 man-days lost in 2010, a substantial

improvement compared to 194 days in 2009.

For our solid waste management business in

Singapore, we saw an increase in the AFR from 4.4 in

2009 to 6.4 in 2010. Its ASR also increased from 92.6 in

2009 to 346.9 in 2010. The increase in its accident rates

was mainly due to two accidents which accounted for

more than 50% of the lost work days, with one case

involving an employee breaking his wrist while the

other saw the employee concerned hurting his back in

the course of work.

Safety remains important to us and our solid waste

management business has taken preventative action to

improve its AFR and ASR levels. This includes additional

’toolbox meetings’ with management and employees

to cover the importance of health and safety and spot

inspections at operational sites.

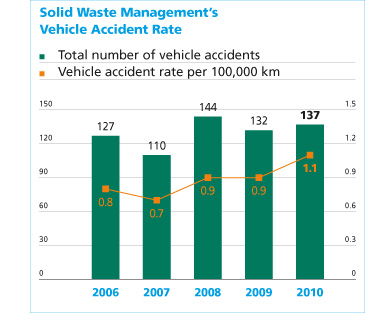

Sembcorp’s solid waste management business

operates a fleet of 170 commercial vehicles and

undertakes a considerable amount of driving each

year. One of our key indicators for this business for

safety is vehicle accidents. In 2010, there was a rise

in the accident rate both in terms of absolute numbers

and number of incidents per 100,000 kilometres driven.

The company has commenced a programme of safety

training for its drivers starting January 2011, and

will continue to track and aim to reduce its vehicle

accident rate. Sembcorp’s solid waste management business

operates a fleet of 170 commercial vehicles and

undertakes a considerable amount of driving each

year. One of our key indicators for this business for

safety is vehicle accidents. In 2010, there was a rise

in the accident rate both in terms of absolute numbers

and number of incidents per 100,000 kilometres driven.

The company has commenced a programme of safety

training for its drivers starting January 2011, and

will continue to track and aim to reduce its vehicle

accident rate.

In 2009, we embarked on an initiative to pull

together our different facilities and operations on

Jurong Island for an integrated ISO14001

Environmental Management System (EMS) certification,

as an effort to align the HSE management certifications.

Backed by strong support from senior management,

we successfully underwent an independent audit and

achieved certification in May 2010. Moving forward,

we have committed to an improvement target to

obtain an integrated certification of the OHSAS18001

Occupational Safety and Health Management System

and the ISO14001 EMS certification for our Singapore

Utilities operations by 2011.

In Singapore, our solid waste management business

under our Utilities business unit received the Flu

Pandemic Preparedness Verification Certificate which

is part of the Singapore Business Federation’s National

Business Continuity Management Programme launched

in 2010.

From 2009 to the end of 2010, we worked to

strengthen our HSE standards at our operations in

Fujairah, UAE. We formalised and enhanced the HSE

management system on the site and completed a

written submission to the local authorities documenting

this enhanced system. Going forward, we aim to work

towards full implementation of the management

system, and to obtain certification to ISO14001 EMS

and OHSAS18001.

In 2010, Sembcorp’s VSIP also obtained the

ISO14001 EMS certification for its environmental

efforts. It is the first industrial park in Vietnam to

receive this certification awarded by Société Générale

de Surveillance (SGS), a leading inspection, verification,

testing and certification company recognised as the

global benchmark for quality and integrity.

Updating our standards and seeking continuous

improvement is part of our Group HSE department’s

mandate. In 2010, a Group HSE workshop was held

where employees from our operations around the

world contributed ideas towards the formulation of

key HSE initiatives as well as a set of global mandatory

HSE guidelines for all business units under our

operational control. Updating our standards and seeking continuous

improvement is part of our Group HSE department’s

mandate. In 2010, a Group HSE workshop was held

where employees from our operations around the

world contributed ideas towards the formulation of

key HSE initiatives as well as a set of global mandatory

HSE guidelines for all business units under our

operational control.

The HSE performance of each business unit was

also presented at the Annual Asset Management and

HSE Workshop in September 2010. HSE incident data

including statistics on injuries, AFR and ASR, spills, non-compliance,

hazardous releases, waste and disposal

and emissions were reported. Significant achievements

and areas for enhancements were also shared for

learning amongst the business units.

In 2010, our Group HSE department continued

with its programme to monitor, review and audit

each business unit’s HSE management system and

performance. In January 2010, a five-day internal

audit for our operations in Fujairah was conducted. The results of this audit were fed into the unit’s

efforts to implement improvements for alignment

to the new UAE Code of Practice, a framework

for the HSE management system. HSE reviews

were also conducted during the year at our water

operations in Nanjing and Zhangjiagang to assess the

implementation of HSE management systems at the

two China sites. Detailed findings and corrective and

improvement actions were presented in a report to

facilitate improvement.

In 2010, the Group HSE office was involved in site

inspections, HSE workshops and events conducted by

the business units as well as training and workshops to

improve HSE performance and manage health, safety

and environment risks associated with our activities,

products and services.

In 2010, training courses on HSE, asset management

and operations and maintenance were held for selected

employees from our China operations, with tailored training materials and presentations conducted

in Mandarin. Similar training was also conducted

for selected employees from Indonesia. The Group

HSE team also conducted a half-day HSE breakout

session during the Group Asset Management and HSE

workshop held for officers from our global operations

in Singapore. This annual event encourages HSE

representatives to network, share best practices, and

contribute to improving our HSE programmes. Ideas

and suggestions contributed by the participants were

collated and considered for incorporation into the

annual Group HSE work plan.

Sembcorp is a signatory of Responsible Care in

Singapore. This is a voluntary initiative of the global

chemical industry for environmental protection,

occupational health and safety, process safety, product

stewardship, distribution, community awareness and

emergency response. In 2010, the Singapore Chemical

Industry Council invited Sembcorp to present on

Responsible Care’s Emergency Response code at its

Responsible Care Good Practices Workshop in August,

where industry players shared good practices with respect

to Responsible Care’s Code of Management Practices.

At Sembcorp, we recognise that our employees

are our most vital assets and a key stakeholder group.

We remain committed to providing a fair, diverse

and inclusive workplace, and to continuous

improvement in our human resource and people

development practices.

This section of the report covers the activities of

Sembcorp Industries’ head office, the Utilities business

unit (which now includes the solid waste management

business), as well as the Industrial Parks, Design

and Construction and Mint business units. We have

expanded data coverage to include operations in all

countries we operate in. Any deviation from this scope

is noted under the individual indicator.

Sembcorp strives to maintain a fair, diverse and

inclusive workplace for all employees. With its headquarters based in Singapore, the Group subscribes

to The Principles of Fair Employment formulated by

the Singapore Tripartite Alliance for Fair Employment

Practices, and has endorsed the Tripartite Alliance’s

Employers’ Pledge of Fair Employment Practices.

These principles, embedded into our human resource

practices and implemented by Sembcorp on a global

level, include a commitment to:

| • |

Recruit and select based on merit, such as skills, experience and ability, regardless of age, race, gender, religion or family status. |

| • |

Treat employees fairly and with respect and implement progressive human resource management systems. |

| • |

Provide equal opportunities for training and development based on employees’ strengths and needs, to help them achieve their full potential. |

| • |

Reward fairly based on ability, performance, contribution and experience. |

| • |

Abide by labour laws and adopt tripartite guidelines which promote fair employment practices. |

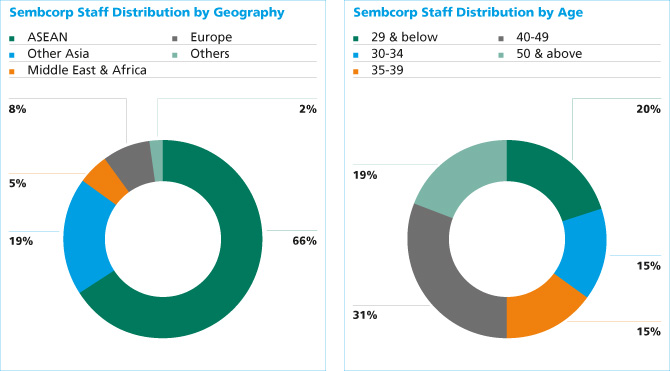

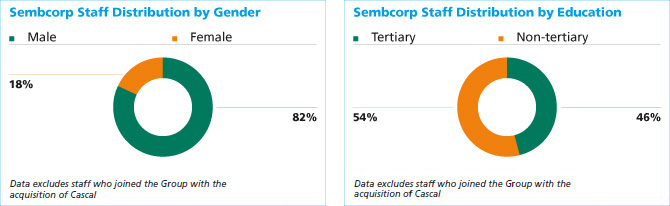

Permanent headcount increased in 2010 with the

acquisition of Cascal and its international municipal

water business. At the end of December 2010, there were about 9,100 permanent employees in the

Sembcorp Group. The Group had a further 5,900

employees working on a contract basis, 80% of whom

work for the Marine business. Please see charts below

for the distribution of Sembcorp’s permanent employees

by geographical region, gender and education.

|

| |

|

Sembcorp fully supports basic principles of

human rights and has implemented a number of

policies throughout the Group in support of these

principles, including fair employment practices and

a grievance and harassment policy. We also offer

equal opportunities with respect to recruitment

and selection.

A key tenet of Sembcorp’s business ethics is strict

respect for labour laws within each of the countries

we operate in. Through our policies and the planning

and administration of our employment practices, we

are confident that our operations are not exposed to

issues such as child or forced labour.

Within the boundaries of each of the legal and regulatory jurisdictions under which we operate, every

Sembcorp employee is entitled to practise freedom

of association in the workplace. At the end of 2010,

there were over 3,000 unionised members in Sembcorp

(including workers under the Marine business),

covering over 30% of our total workforce.

Sembcorp maintains constructive ongoing

exchanges with employee unions in its various

locations. For instance, in the UK, discussions with

Unite, the UK’s biggest union, are conducted in

line with our collective agreement, the ’Together

Agreement’ which covers over 90% of employees at

our Teesside operations. Also in the UK, our municipal

water operations, Sembcorp Bournemouth Water,

has had a long-standing positive relationship with its

recognised unions, GMB and Unison. Both unions are

represented on the unit’s Staff Consultative Group and

Health and Safety Committee, and also participate in

safety inspections. In Singapore, Sembcorp’s various

business units hold regular meetings with the two main

unions, the Union of Power and Gas Employees, as

well as the Building Construction and Timber Industries

Employees’ Union (BATU) to discuss various issues

to help our employees stay competitive. Collective

discussions in 2010 involved annual increments,

variable bonuses and worker skills in specific sectors.

Sembcorp recognises the importance of engaging our

employees. We operate a number of channels through

which we communicate with and receive feedback from

our employees. We provide information on our financial

and business performance, as well as on applicable

company standards and policies to our staff. Interactive staff communications sessions with management are in

place to ensure two-way communication between the

company and its employees.

In 2010, we continued to hold employee briefing

sessions in conjunction with the company’s quarterly

financial reporting cycle. At these sessions, held in

an interactive setting, senior management provides

employees with a first-hand account of the company’s

performance and key developments for the quarter.

In addition, we continued to hold an annual

communication forum in Singapore for managers from

Sembcorp offices all over the world, with in-depth

briefings from top management and invited experts

on our Group’s operating environment, performance,

outlook and strategy. This forum incorporates an

interactive networking and question-and-answer session.

Furthermore, at the country level, some business units

also held quarterly learning and sharing sessions, senior

manager briefings, and staff consultation group sessions.

Over the course of the year, we continued to

communicate corporate updates and business milestones

to all staff through employee email blasts and our

employee e-newsletters. Relevant and up-to-date

information on staff welfare and benefits was also

publicised to employees via the company intranet.

Sembcorp welcomes feedback from its employees

and provides confidential channels through which

employees can submit feedback and staff suggestions,

including an easily-accessible online form on the

employee intranet. All feedback is sent to the Group

Human Resource department, and is also automatically

copied to the Director for Group Human Resource and

to the Group President & CEO’s office if sent via the

staff intranet.

In line with our commitment to high ethical

standards and good corporate governance practices,

we operate a group-wide whistle-blowing policy

and encourage all employees to report any possible

perceived improprieties on a confidential basis and

without fear of recrimination. We have an easily-accessible

whistle-blowing link on our company

intranet, and employees may also provide whistle-blowing

feedback via channels including mail,

email and fax.

Sembcorp continues to promote a holistic and

balanced lifestyle for our employees, which we

believe is good for both their physical and mental

health. We encourage employees at our various business

units to participate in employee recreation events throughout the year, including community outreach

and volunteering events, team sports events, talks,

gatherings and employee family days. We also opened

up some of these activities to include employees’ family

members, such as our Family Day for employees from

Singapore operations. In 2010, we spent over S$100,000

on wellness programmes for employees in Singapore. Sembcorp continues to promote a holistic and

balanced lifestyle for our employees, which we

believe is good for both their physical and mental

health. We encourage employees at our various business

units to participate in employee recreation events throughout the year, including community outreach

and volunteering events, team sports events, talks,

gatherings and employee family days. We also opened

up some of these activities to include employees’ family

members, such as our Family Day for employees from

Singapore operations. In 2010, we spent over S$100,000

on wellness programmes for employees in Singapore.

In Singapore, we are also part of the iCare Mental

Health Alliance, which seeks to promote workplace

mental health and offers employees access to

counselling and assistance programmes, including

retirement preparation and workplace accident-related

trauma counselling.

Our shared success at Sembcorp is driven by

the calibre and performance of our people. We recognise that it is essential to equip our employees across all

levels of seniority to meet the changing needs of the

marketplace. Sembcorp offers employees a range of

personal and professional development opportunities

including career development, education, talent

management and leadership programmes. to equip our employees across all

levels of seniority to meet the changing needs of the

marketplace. Sembcorp offers employees a range of

personal and professional development opportunities

including career development, education, talent

management and leadership programmes.

In 2010, the Group continued to invest in

competency building for our employees, spending

S$1.6 million on training for employees in Singapore

alone. It is a priority for us to enhance the skills

levels of our employees to ensure smooth succession.

Sembcorp’s learning and development programmes

factor in issues such as succession planning and

addressing skills gaps with relation to core competency

requirements. About 1.7% of our employees in

Singapore are due for retirement in the next five years.

Our training and development programmes include:

| • |

The ’Sembcorp Leadership Competencies’ is

our unique talent management and development

system that defines the qualities and performance

expectations of a Sembcorp leader. Capable leaders

are a crucial component in achieving extraordinary

business success and this set of competencies details

the ways in which Sembcorp leaders should act and

respond. Managers also attend courses to enhance

their presentation, negotiation, communication and

coaching skills, as well as courses on building and

leading high-performance teams.

Senior executives are expected to undertake

regular training to update and upgrade their skills,

and education programmes are accessible for them at

prestigious institutes such as the Harvard Business School,

INSEAD and the Temasek Business Leadership Centre. |

| • |

At Sembcorp, we offer employees experience in

different cultural and operational settings through job

rotations and attachments. For instance, we currently

have more than 50 employees of different nationalities

posted from our Singapore office to various overseas

businesses. Internships and industrial attachments also

provide students and Sembcorp scholars with practical

experience and exposure to our operations whilst they

undergo their studies.

Overseas site visits are also useful in offering

employees exposure and in promoting the sharing of

expertise across Sembcorp’s international operations.

For instance, in 2010 we held a series of working tours

and development visits for China-based employees at

our facilities on Jurong Island, Singapore. |

| • |

At Sembcorp, we send our employees for professional

training to allow them to develop skill sets to equip

them to better perform their jobs.

Working with local educational institutions,

Sembcorp has developed and conducted specialised

technical courses for the Utilities business, including

a certified energy manager course by the Institute of

Engineers in Singapore and a basic boiler and cooling

water treatment course by Nalco, a leading process

improvement company serving the industrial water

and energy industries. Sembcorp also sends many

of our employees for professional training related

to the industry, including courses under Singapore’s

National Skills Recognition Scheme and Workforce

Skills Qualification scheme under the Workforce

Development Authority.

Overseas, our employees also continued to receive

training. For example, selected employees at our

operations in Mbombela, South Africa, underwent

Adult Basic Education and Training to equip them with

foundation skills in areas such as English, mathematical

and computer literacy.

In addition, we also run on-the-job training for

our employees. |

| • |

As an industry leader in various sectors, Sembcorp

encourages our employees to share and exchange

best practices through platforms such as seminars and

conferences on a local and international basis. |

Sembcorp has implemented a standard system for

performance appraisals across our operations in various

countries. The appraisal system allows employees to

comment on their personal contribution throughout

the year and to jointly identify areas for further career

development and learning with their supervisors. It

enables constructive discussion and uses the feedback

process to ensure that employees share the responsibility

for managing their career and goals. The appraisal

process incorporates shared future objectives to ensure

that employee outputs are also aligned to the needs of

the business.

Selected senior managers are also assessed using a

360-degree appraisal system where feedback is sought

from a range of superiors, peers and colleagues and

other partners. The profile of essential competencies

for the job function compiled from this process is also

incorporated into these managers’ development plans,

helping them to lead their teams successfully and

enhance their professional performance.

Rewarding performance is a cornerstone of

Sembcorp’s employee retention strategy. The Group

offers competitive base pay packages throughout our

global businesses that are based on country-specific

conditions. Rewards include annual salary increments

and annual performance bonuses, as well as longer-term

incentives linked to sector practices and based

on the performance of the Group, the company and

the individual.

Share-based incentives, administered by a board-nominated committee, remain a key component

of the Group’s pay structure and are deliberately

aligned to long-term Group performance objectives.

Since 2007, share options granted to staff have been

replaced with restricted stocks of equivalent fair value.

This Restricted Share Plan applies to employees of the

Group, while the Performance Share Plan is aimed

primarily at key executives of the Group.

All employees are eligible for comprehensive

insurance coverage on a global basis. They can join

the company’s private medical insurance scheme,

under which the company meets the cost of employee

membership and allows employees to include eligible

dependants. The company also provides additional

insurance cover for life, travel, personal accidents,

workers’ compensation and hospitalisation and

surgical requirements.

In Singapore, where 86% of Sembcorp’s contract

workers are employed, we require contractors to

comply with all requirements stated in a Permit to

Work application issued by the Ministry of Manpower,

before they can work in our facilities or operating

sites. This includes requirements for health and safety

provisions and the submission of proper paperwork

to demonstrate the presence of adequate workers’

compensation insurance coverage, as well as relevant

resident visa and work permits. Employees of our

contractors must also attend health, safety and

environment training before any work is started.

As an active corporate citizen, Sembcorp

maintains an ongoing commitment to contribute to

the local communities in which we operate through

supporting social development and community

investment projects. In 2010, Sembcorp contributed

over S$1 million in cash and in kind to its communities,

excluding community investment initiatives by our

separately-listed Marine business. We took part

in many initiatives in our communities in support

of children and the elderly, education, sports and

fitness and the environment, amongst others. We

also provided management time and support for

volunteer programmes.

Our employees actively participate in volunteerism

initiatives that the company organises. For example, in Singapore, our employees participated in fundraising

activities organised by the Assisi Hospice and volunteered to help clean the homes of the needy

elderly under the care of Sunshine Welfare Action

Mission. In Singapore, our employees spent more than

1,800 hours on volunteerism in 2010. Our employees

overseas also participated in volunteerism initiatives.

For instance, employees from our operations in

Bournemouth in the UK support and promote the

work of international water charity, WaterAid, through

giving presentations to schools, groups and clubs in

their local area on WaterAid’s work.

Sembcorp supports projects that help to support

outreach activities to the communities. For instance,

in Singapore, Sembcorp supported the National Parks

Board’s initiative to enhance and promote appreciation

of biodiversity through the launch of the Sembcorp

Forest of Giants.

During the year, Sembcorp also continued to

contribute to programmes in aid of sports and in

support of young sportsmen pursuing their dreams. In

Singapore, we sponsored S$50,000 worth of scholarships

and bursaries for promising young badminton players

through an ongoing programme jointly administered by the company and the Singapore Badminton Association.

In addition, we also pledged S$300,000 over three years

to the Singapore Table Tennis Association towards

support of the national table tennis team as well as

the association’s efforts to raise the level of the game

locally and help to nurture more table tennis talents.

Siza Water, our operations in South Africa, administers

a Youth and Community Development Fund which

sponsors schools with sports equipment and gear to

support students at sports games.

We have taken part in many initiatives supporting

children and education. For instance our operations in

Teesside in the UK helped organise educational visits to

our facilities at Sembcorp’s Wilton International,

a chemical manufacturing site at Teesside.

Sembcorp also contributed to programmes

supporting wildlife and biodiversity. For instance,

Sembcorp municipal water operations in Bournemouth,

UK continued to maintain its long-standing support of

Dorset Wildlife Trust, which has more than 40 nature

reserves covering 1,300 hectares of wildlife habitat

and five education centres in the local area. In addition,

during the year the unit donated one of its former

vans to local volunteer wildlife aid group Dorset

Wildlife Rescue (DWR) to be used as an ambulance

for transporting injured, sick or orphaned wild

mammals and birds of prey across Dorset, Hampshire

and Wiltshire.

For further information on sustainability at Sembcorp Industries, please visit our website at www.sembcorp.com. If you have any comments or wish to discuss any of the contents of this report or other sustainability issues, please contact:

Group Corporate Relations

Tel: +65 6723 3113

Email: [email protected] |

| |

|

|

|

|