|

|

|

|

|

| |

|

| |

Sembcorp’s priority is to deliver long-term value

and sustainable returns to its shareholders. As a

multinational enterprise and a public listed company,

we understand that there is a complex value chain

to which Sembcorp belongs and that our wider

responsibility incorporates sustainability issues. We

recognise that these issues may be outside the

traditional view of corporate activity, but as the global

business landscape evolves, managing these issues is

increasingly viewed as vital in maintaining a company’s

‘licence to operate’ by society and our stakeholders.

This widening role of business is taken seriously

and is reflected in Sembcorp’s commitment to

excellence and continuous improvement. In late 2011,

we established a Sustainability Steering Committee

to drive Sembcorp’s sustainability performance and

to develop our priorities across the Group. The

Committee will also review our sustainability roadmap

and make strategic recommendations to improve

sustainability performance across the organisation.

The Committee is chaired by the Chief Health, Safety

and Environment Officer and Executive Vice President

of Group Asset Management.

Sembcorp’s management and monitoring of

sustainability issues is based on a risk management

approach. Issues that are material to Sembcorp and

our stakeholders are reviewed on an ongoing basis as

the company continues to expand. In late 2011, a

materiality review was conducted by an independent

consultant to identify the company’s key sustainability

issues. This involved identifying potential issues

and prioritising them based on a Materiality Matrix

approach, which charts their level of importance

to Sembcorp and our stakeholders, using clearly

defined materiality criteria. The initial findings of the

review identified key sustainability issues such as

environmental protection and safety. We will be

taking steps to engage our key stakeholders on the

findings of this initial review.

Sembcorp is an international company with

customers and operations around the world. In 2011,

we focused on enhancing our sustainability data

management systems and as a result, we have been

able to broaden the scope of our sustainability

reporting this year. The data in this year’s report

covers all our Utilities business units where Sembcorp

has either operational control or majority ownership

in Singapore, China, the UAE, UK and Vietnam. We

have also been able to include data from our China

and UK municipal water operations which we

acquired in 2010.

Our Marine business is excluded from this report,

as it is separately listed in Singapore and reports its

activities separately. Our target for our ongoing

reporting is to incorporate data from all businesses

in which Sembcorp has a majority stake or

operational control.

Data and activities for key performance indicators

for the included operations have been tracked and

reported in the areas of:

| |

|

| • |

Health, safety and environment |

| • |

Human resource and employee welfare |

| • |

Wider community |

| |

|

Where data is unavailable or has been excluded,

this has been clearly stated. All data measurement

is in line with Global Reporting Initiative (GRI) G3.1

recommendations for our chosen indicators.

Further information on the company’s corporate

governance, risk management & mitigation strategies

and investor relations, all of which are part of our

wider remit of sustainability, can be found in the

relevant chapters under the Environmental, Social &

Governance Review section of this annual report.

Sembcorp has included aspects of sustainability

in our annual report since 2001 and was one of

the first companies listed on the Singapore

Stock Exchange to publish a voluntary sustainability

report using the GRI G3 guidelines. We continue

to use the reporting principles and framework

of GRI and have considered its principles in

terms of materiality, stakeholder inclusiveness,

sustainability context, completeness, accuracy

and comparability. This report is checked against

the GRI G3.1 Framework as Application Level B

and addresses activities and data that fall within

the company’s financial year for the period from

January 1 to December 31, 2011.

In line with our continuous drive for innovation

and to widen our sustainable business portfolio, the

development of sustainable or green business lines

has become a growing part of our ongoing business.

Our sustainable products and services deliver an

additional competitive edge to our customers,

enabling them to achieve their sustainability and

environmental goals. Our sustainable business

operations include the following:

In December 2011, Sembcorp commenced

operations of our woodchip-fuelled biomass steam

production plant on Jurong Island, Singapore. The

plant produces up to 20 tonnes of steam per hour for customers using waste wood collected from

industrial and commercial waste and processed by

our solid waste collection business. For more details

on the plant, please refer to the write-up

on energy-from-waste solutions below.

Meanwhile, in the UK, the Sembcorp Biomass

Power Station in Teesside uses sustainable wood for

fuel. The 35-megawatt combined heat and power

plant is the first large scale wood-fired renewable

energy plant in the country and saves 200,000

tonnes of carbon dioxide emissions a year.

Sembcorp is Singapore’s first commercial importer

and retailer of natural gas, considered the cleanest

of all fossil fuels. Since 2001, we have been

importing 341 billion British thermal units of natural

gas per day from West Natuna in Indonesia

and supplying it to major power generators and

petrochemical companies. From the fourth quarter of

2011, we started importing an additional 90 billion

British thermal units of gas per day.

Sembcorp aims to apply technology to achieve

greater efficiency and lower emissions in our power,

steam and desalination operations. A summary of

our use of such technologies may be seen in the

table below.

In May 2010, Sembcorp announced a joint

venture agreement with Gayatri Energy Ventures

to build, own and operate a 1,320-megawatt

coal-fired power plant in Andhra Pradesh, India.

While the plant will be fired by coal, it will utilise

supercritical technology which reduces emissions

of carbon dioxide and other pollutants by consuming

less fuel per unit of electricity generated, reducing

its associated environmental impacts. Sembcorp

expects the power plant to be substantially fuelled

by low sulphur non-coking coal.

Sembcorp’s water business is actively playing

a part in providing sustainable water solutions

to meet the growing needs of industries and

communities and support ongoing development

in emerging economies. We supply water to over

five million people worldwide through our municipal

water operations and also support the specialised

water needs of industrial companies while reducing

their impact on the environment.

Sembcorp owns and operates facilities capable

of treating high organic concentration and high

salinity industrial wastewater. Our industrial

wastewater treatment facilities in China and

Singapore are capable of treating wastewater up

to 20 times more concentrated than municipal

sewage and up to 1.5 times more saline than

seawater. By treating our industrial customers’

wastewater to meet discharge standards, we help

industries limit their impact on the environment.

In Singapore, our largest industrial wastewater

treatment plant on Jurong Island is expected to

commence operations in the second half of 2012.

The 9,600 cubic metres per day plant is capable

of treating multiple streams of complex industrial

wastewater and will more than double our current

capacity on the island.

We were the first company in China to be

allowed to treat highly concentrated industrial

wastewater directly from source without requiring

our customers to invest in pre-treatment facilities.

Chinese government regulations require industrial

companies to pre-treat their wastewater to the

standard of municipal sewage before discharging

the wastewater to a standard sewage treatment

plant. The decision to permit industrial companies

to discharge effluent directly to our wastewater

treatment facility signifies a new milestone for

advanced wastewater management in China.

Beyond treating wastewater, Sembcorp also

reclaims water from treated effluent. This integrated

closed loop approach minimises liquid discharge,

conserves precious water resources and offers a

sustainably-sourced alternative water supply to

industries and households. In Singapore, we are

a pioneer in reclaiming industrial effluent on Jurong

Island. In China, we opened our first industrial water

reclamation plant in the Zhangjiagang Free Trade Port

Zone which is capable of reclaiming industrial water

from treated effluent for reuse by industries. Our

industrial wastewater treatment and water reclamation

facilities in the area have been selected by the

governments of Singapore and China as Government-to-Government showcases for bilateral cooperation in

water management, and won prestigious Honour

Awards at both the East Asian and Global International

Water Association Project Innovation Awards in 2010.

Our NEWater plant in Singapore, capable of

producing 228,000 cubic metres per day of water, is one

of the largest water reclamation plants in the world and

plays a significant part in Singapore’s water sustainability

journey. It won the Water Reuse Project of the Year at

the Global Water Awards 2010, which recognises the

water reuse project that represents the most significant

achievement for the industry internationally.

We provide sustainable water supply through

desalination to meet growing water demand. Our

US$1.7 billion plant in Fujairah, UAE and our

upcoming US$1 billion plant in Salalah, Oman,

have a water capacity of 100 million and 15 million

imperial gallons per day of desalinated water

respectively. Both integrated power and desalination

plants use various desalination technologies such

as multi-stage flash and reverse osmosis.

Through Sembcorp’s range of services, waste

that would usually be disposed of in landfills

and incineration facilities is diverted for recycling.

Within the Sembcorp Group, we have capabilities

in advanced waste treatment and resource recovery,

including composting and waste-to-resource. Our

waste-to-resource facilities in Singapore extract

recyclables from waste collected through our waste

collection arm, which is the leading operator in

Singapore serving five out of the nation’s nine

municipal sectors. Sembcorp also operates a

construction and demolition materials recovery

facility in Singapore recovering timber, hardcore

and fines, as well as ferrous and non-ferrous metals.

Waste wood collected is processed and used to fuel

our new woodchip-fuelled biomass steam production

plant to produce steam for our customers.

Furthermore, a comprehensive range of waste paper

recycling services is offered from collection, sorting

and baling to bulk supply of recovered paper to

paper manufacturers.

Sembcorp develops self-sufficient integrated

urban developments comprising industrial parks as

well as business, commercial and residential space.

The business’ integrated approach to delivering

urban work and living environments attracts local

and international investments which facilitate

development, promotes a conducive business

environment and creates jobs for locals.

Sembcorp manages integrated urban

developments with a total gross project size of

7,687 hectares. The integrated developments are

master planned with proper zoning of industrial,

commercial and residential areas, and have strict

effluent discharge guidelines to prevent toxic

discharge into the environment. In addition, on-site

sewage treatment plants treat the effluent before

discharge. Where possible, conservation of the

natural environment and preservation of greenery are

incorporated into the master plans.

Our fourth Vietnam Singapore Industrial Park

development in Hai Phong, Vietnam, incorporates

conservation considerations into its master plan,

with 30% of the land within the development

reserved for green space and preservation of local

flora and fauna. Existing wetlands on the site as well

as tributaries from the Cam River running through

the property will be preserved and made a feature

of the development, while two large retention

ponds will be created to aid water flow during the

monsoon season. These ponds integrate with the

community’s leisure space, while providing a source

of water for landscaping.

Our joint venture project in China, Sino-Singapore Nanjing Eco Hi-tech Island, is envisioned

as a world-class integrated urban development

on a green island which will have more than

50% of its area preserved for eco-tourism. It will

also feature an exhibition centre and a research

and development park with green roofs to alleviate

urban heat effect as well as rain collection canopies.

Wetland biofilters and park connectors are also

incorporated into the integrated development’s

overall design plan.

In 2011, we added a new development to our

portfolio, the 1,000-hectare Singapore-Sichuan

Hi-tech Innovation Park in China. With the promotion

of research and development, high-tech upgrading

and environmental protection among the central

government’s twelfth “Five Year Plan” objectives,

the park will focus on technology-driven, knowledge-intensive

industries and showcase a modern,

innovative and low carbon emission city.

Sembcorp recognises that its business operations

are intertwined with various stakeholders. In early

2012 we conducted a stakeholder engagement

planning exercise in line with AA1000 Stakeholder

Engagement Standard with the help of an

independent consultant to review and identify

our key stakeholder groups.

Sembcorp’s key sustainability stakeholder

groups have been identified as shareholders,

financial institutions, the investment community,

government, regulators, customers, employees and

members of communities where we have operations.

Our internal stakeholders are crucial in our

day-to-day practice of sustainability and in

determining our sustainability-related risks and

identifying areas for future improvement. As part

of our efforts to create a culture of open two-way

communication, employees are encouraged to

contribute ideas on improving workplace

practices and the delivery of products and

services. This includes feedback on issues such

as dishonesty and fraud via our whistle-blowing

scheme and confidential feedback channels. To

further promote sustainability as a part of

Sembcorp’s corporate culture, employee appraisals

take into account HSE performance as appropriate.

For further information on employee engagement, please click here.

Sembcorp maintains open communication

channels with the investment community including

shareholders, analysts and potential investors. We

actively engage our stakeholders through various

platforms such as one-to-one meetings, group

meetings, presentations and site visits. In 2011,

we had over 130 meetings with the investment

community. Further information on such

communication can be found in the Corporate Governance and Investor Relations chapters.

We engage in regular dialogues with the

government, regulator and community through

different platforms such as meetings, briefings and

presentations. For example, our solid waste

management operations in Singapore hold monthly

meetings with the respective town councils of every

municipality that we serve.

We proactively engage with customers to find

out how we can improve our services. In the UK,

focus groups and internal surveys are conducted

annually to find out how our municipal water

operations can enhance or improve our service

offering. These also help identify key drivers of

satisfaction, so we know where to focus our efforts

and investment. All feedback is used to make

improvements either via training of advisors,

enhancements to existing processes or the

development of new service enhancements. Our

operation in Bournemouth, UK, is currently

developing a framework to form a customer

engagement panel for the next review of prices by

the regulator. In Singapore, our Utilities operations

conduct a bi-annual survey with its gas, power and

utilities customers. The online survey is sent to all

customers, and in 2010, the overall customer

satisfaction rate was 95%. Aside from the survey,

customers have access to an online portal to retrieve

their consumption information, and they can provide

further feedback via email or a hotline telephone

number. Our solid waste management operations

also conduct an annual online survey with its

customers, and provide a hotline number as well as

an email address for further feedback.

Through these and other formal engagement

programmes, we aim to continue to align relevant

stakeholder issues with our overall strategy.

Sembcorp has a complex supply chain and our

actions influence many businesses along the value

chains we operate in. Many clients are in the process

of developing their own sustainability programmes. As

a provider of essential solutions, we aim to assist our

customers to improve their HSE performance, limit

their environmental impact and conserve resources.

As a provider of utilities, Sembcorp directly

consumes primary resources, produces waste and

emissions and manages people, buildings, treatment

processes and machinery. As such, we work closely

with our suppliers, business partners and contractors

to ensure adherence to our Group HSE guidelines.

All suppliers are subject to a vendor pre-qualification

review that includes checks on its HSE provisions. We

ensure that the appointment of all vendors and

contractors comply with the applicable government

certification requirements as well as our guidelines

and policies. Platforms such as safety induction

programmes and contractor HSE engagement help

to actively identify gaps and improve performance.

In Singapore, where over 70% of Sembcorp’s

contract workers are employed, we require

contractors to comply with all requirements stated

in a Permit to Work application, issued by the

Ministry of Manpower, before they can work in our

facilities or operating sites. This includes requirements

for health and safety provisions and the submission

of proper paperwork to demonstrate the presence

of adequate workers’ compensation insurance

coverage, as well as relevant resident visa and work

permits. Employees of our contractors must also

attend HSE training before any work is started.

At Sembcorp, we recognise the importance

of being an active player within our industry and

engaging with our peers and the wider business

community on sustainability issues. Sembcorp is a

founding member and supporter of the Singapore

Compact for Corporate Social Responsibility,

a national society promoting sustainability issues

in Singapore.

Our Group President & CEO also serves as a

member of Singapore’s Climate Change Network,

a forum started by Singapore’s National Climate

Change Secretariat. The network serves as a

platform for representatives from various sectors

to nurture dialogue on climate change matters and

to exchange information on climate change issues.

At the industry level, Sembcorp participates in

the Responsible Care voluntary initiative, endorsed

by the Singapore Chemical Industry Council (SCIC).

This encourages members to adopt 10 guiding

principles for a safer chemical industry through

the six management practices of employee health

and safety, distribution, pollution prevention,

process safety, product stewardship and community

awareness, and emergency response. Our Utilities

business in Singapore has actively participated in a

number of industry workgroups organised by the

SCIC looking at issues such as capacity building on

process safety and drafting new quantitative risk

assessment guidelines.

In Singapore, Sembcorp is also a member of

the Sakra Island Community Awareness Group,

which seeks to promote community awareness

and a standardised management practice code for

emergency responses among companies located

in the Sakra district on Jurong Island. Similarly,

our Teesside, UK operations are active in the North

East of England Process Industry Cluster which serves

as a unified voice for the process industry in

Northeast England, where a substantial part of the

UK’s chemical, petrochemical, speciality chemical,

pharmaceutical, polymer and biotechnology

industries are based. In the UAE, our operations in

Fujairah are part of the Abu Dhabi Water & Electricity

Authority’s task force in formulating HSE procedures

and guidelines for the energy sector.

In 2011, Sembcorp received both national and

global recognition and a number of awards for its

efforts to promote and practise sustainability.

Sembcorp has been selected as an index

component of the Dow Jones Sustainability Asia

Pacific Index for 2011. The index represents the top

20% of the largest 600 companies in the Asia Pacific

developed region based on long-term economic,

environmental and social criteria. Sembcorp is

honoured to be one of only four Singapore

companies selected for the index.

Sembcorp clinched the coveted Gold award

for Best Annual Report (for companies with

S$1 billion and above in market capitalisation) at

the Singapore Corporate Awards 2011 for our

Annual Report 2010, in recognition of our excellence

in reporting and disclosure. The prestigious awards

showcase excellence in corporate governance and

shareholder communication, and the Best Annual

Report award was introduced to encourage social

responsibility reporting as well as increase the

awareness of the organisations’ responsibility to

the community.

Sembcorp won the Frost & Sullivan Asia Pacific

Waste Recycling Company of the Year award in

2011, in recognition of our excellence in solid

waste recycling, waste treatment support and

applying environmentally-friendly waste recycling

technologies in our businesses. The award also

recognises the company’s position as a major

industry player providing waste recycling services

across customer verticals, and our ability to

successfully respond to our customers’ needs

with a business strategy that incorporates best

sustainable practices.

Sembcorp was named the Most Transparent

Company (multi-industry / conglomerates category)

at the Securities Investors Association (Singapore)

Investors’ Choice Awards 2011 for the third year

running. This recognises our continuous drive

towards transparency and good governance,

and our efforts to give stakeholders an accurate,

coherent and balanced account of our company

and performance.

Sembcorp was conferred top honours at the

Singapore Sustainability Awards 2011, winning the

Sustainable Business Award (Enterprise category).

The awards, presented by the Singapore Business

Federation, recognise local enterprises with

outstanding sustainable business practices.

Companies are assessed on their innovation,

corporate social responsibility, commercial potential

and sustainable business growth, as well as their

environmental, health and safety and production

process management systems.

Sembcorp was honoured by the SCIC with gold

awards in the categories of Community Awareness

and Emergency Response and Pollution Prevention,

and three achievement awards in Distribution,

Employee Health and Safety and Process Safety at

the Responsible Care Awards 2011. The awards

honour companies who have incorporated

Responsible Care management practices into their

operations and recognise those with exemplary

performance in maintaining high HSE standards.

In recognition of our continuing efforts

to provide water and sanitation services of the

highest quality, both Sembcorp’s South African

operations were awarded the prestigious Blue

Drop and Green Drop status in 2011 by the

Department of Water and Environmental Affairs.

Only 7.2% of all water systems in South Africa

were awarded the Blue Drop (drinking water quality

management) status in 2011, while the Green Drop

(wastewater quality management) status was

achieved by only 4.7% of South Africa’s wastewater

systems. In addition, one of our operations was

conferred the Platinum status for achieving the

Blue Drop status for three consecutive years, making

it among just 10 operations in the country to be

awarded Platinum.

HSE issues are clearly linked to Sembcorp’s

long-term success and have been identified as

material factors in terms of their potential impact on

our business operations. In managing our HSE issues,

we continue to be guided by four main principles:

| • |

Implementing internationally recognised HSE

management systems such as ISO 14001:2004

and OHSAS 18001:2007 |

| • |

Actively investing in financially viable

sustainable business lines, which form part of

our core operations |

| • |

Using continuous improvement to enhance

HSE performance of our processes, products

and services |

| • |

Working closely with our business partners and

seeking active engagement to promote mutual

HSE performance improvement |

Sembcorp’s operations are in various phases of

development. They include facilities that are under

construction, newly commissioned as well as recently

acquired. As such, our priority continues to be on

aligning and improving standards across the Group and proactively managing HSE performance

throughout the asset management life cycle,

from business development and project conception,

to operation and the end of the asset life.

With operations that spread across six continents,

our Group HSE department is the driver of our

management systems and coordinates our global

HSE efforts. Management committees and reporting

structures have been established with regional

coordinators working closely with the department.

This ensures the effective management of HSE issues

with the purpose of setting long-term HSE objectives

and targets and complying with regulatory

requirements, voluntary group guidelines, standards

and initiatives. Reporting to the Board Risk

Committee (BRC) was formalised in 2011, and HSE

issues have been incorporated into regular reports

to the board with key HSE risks and controls also

presented to the BRC.

The key goal for the Group HSE department in

2011 was to strengthen overall Sembcorp Group HSE

culture, create more HSE awareness and shape the

development of the HSE management framework

across the Group. The framework outlines the roles

and responsibilities of various relevant departments and business units, in line with the Group HSE policy. The Group HSE policy can be viewed on our website at www.sembcorp.com.

The framework was endorsed by the BRC and

implemented across all Utilities businesses in the

Group. Periodic HSE assurance audits help to ensure

that HSE matters are managed professionally in order

to meet legal compliance and ensure continuous

improvement in all our activities.

In an effort to standardise HSE guidelines and

reporting, Group HSE has reviewed and developed

a standardised set of reporting parameters to track

and monitor key HSE statistics across the Group.

The new parameters and template are based on

the Sembcorp 4/0 targets. The 4/0 targets refer to:

zero harm to people, zero damage to the

environment, zero damage to assets and zero

non-compliance to legal and regulatory requirements.

Along with the Group HSE guidelines, the 4/0 targets

and reporting parameters were approved by the

BRC in February 2011.

It is compulsory for all business units under the

operational control of the Sembcorp Group to follow

these guidelines.

A Group HSE workshop is conducted annually

where employees from our operations around the

world will meet and contribute ideas towards the

formulation of key HSE initiatives as well as a set of

global mandatory HSE guidelines for all business

units under our operational control.

In addition, in 2011, Group HSE also conducted

an inaugural HSE workshop for Sembcorp’s China

operations, with the objective of promoting HSE

awareness and best practice. This resulted in the

establishment of a China HSE Committee comprising

representatives from each site, providing a platform

for HSE colleagues in China to communicate,

share best practices and support improvements in

HSE. Moving forward, Group HSE and Group

Asset Management will support the coordination

of a regular asset management and HSE workshop

to support China’s operations and its HSE

performance improvement.

Group HSE conducts regular HSE audits for

the operations to achieve continuous improvement.

In 2011, we covered our operations in Fujairah,

UAE, and three facilities in China. The audits were

conducted in accordance with Group HSE guidelines,

to help identify and bridge gaps so that these

business units can improve on their HSE

performance. Our water operations in China have

also embarked on automating their reporting

of HSE and operational statistics through

collaboration with the Group HSE and Group

Performance Management departments.

Sembcorp’s two greenfield projects in India

and Oman are in the construction and commissioning

phases respectively. Group HSE works closely

with their counterparts at the new plants to share

and communicate Group HSE guidelines and

requirements. The team visited the plant in Oman

for a two-day HSE review in November 2011, and

established an understanding of the plant’s HSE

management system framework and existing HSE

practices. Potential areas for improvement were

identified and recommendations were made for

establishing HSE procedures and processes.

We continue to work towards implementing

internationally recognised HSE management systems

across our operations.

In early 2012, Sembcorp Gulf O&M Company in

the UAE underwent a certification audit for both ISO

14001 and OHSAS 18001 and was awarded both

certifications with zero non-conformities. Following

these certifications, we will be working towards the

additional requirement of attaining the Abu Dhabi

Environment, Health and Safety Management System

qualification, for which assessments will conclude by

end 2012.

Meanwhile, Sembcorp Utilities Singapore

obtained the integrated OHSAS 18001 and ISO

14001 Environmental Management System in

March 2011.

As a key player in the energy and water sector,

we are keenly aware of global climate change issues.

We aim to limit and manage the impact of our

operations on the environment by enhancing our

efficiency and investing in assets which apply

technologies to manage and reduce emissions. For

example, our new woodchip-fuelled biomass steam

production plant in Singapore produces process

steam for third-party commercial customers. The

plant was designed to the Building and Construction

Authority’s Green Mark Gold standard, and

incorporates natural ventilation and lighting, solar

power and recycled building materials.

Environmental studies including environmental

impact assessments are a part of Group HSE’s

requirements for new major projects and expansions.

Environmental impact assessments are carried out in

accordance with national and / or international

standards and methodologies. All recommendations

put forth from the assessments form part of our

management of HSE risks and are incorporated in the

planning, design, construction and commissioning of

the new plants. Other environmental assessments

such as environmental baseline studies and pollution

control studies are conducted as required in the

relevant countries.

In 2011, we have included data on our

environmental management from our operations

in Singapore, China, the UAE, UK and Vietnam. We

continued to track our primary energy sources usage.

Natural gas still accounts for the largest proportion

of our fuels used. We also monitored indirect energy

usage in the form of electricity consumption by our

operations within the scope of the report.

We are proactive in seeking to reduce our energy consumption and corresponding greenhouse gas emissions through investing in energy efficient and renewable energy technologies. In Singapore, our energy-from-waste technology, which converts organic waste into biogas, has led to a reduction in the consumption of over six million megajoules of natural gas. In Bournemouth in the UK, our operations used 244 megawatt-hours less of grid electricity compared to the previous year. Standby generation was also reduced, saving 6,028 litres of

gasoil which led to a reduction of over 150 tonnes of carbon dioxide emissions. Photovoltaic cells will be installed to generate clean electricity for the plant. In addition, pumps will be refurbished to ensure efficiency during operation. For a summary of the energy efficiency technologies which we apply in our operations, please click here.

Our carbon dioxide emission estimate1 is derived

from stationary fuel combustion and does not cover

process emissions. In 2011, our carbon dioxide

emission amounted to over 6,500 kilotonnes as

compared to over 7,600 kilotonnes in 2010. Our

emissions estimate is based on the World Resource

Institute / World Business Council for Sustainable

Development Protocol as well as site specific data.

1 Emission data excludes plants in China which are not stationary fuel combustion plants

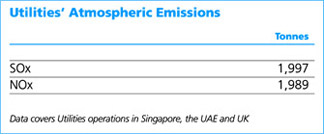

In addition to carbon dioxide and greenhouse gas

emissions, we monitor emissions of sulphur oxides

(SOx) and nitrogen oxides (NOx). The data tracked is

from our energy generation operations in Singapore,

the UAE and UK. Our operation in Teesside is the main

contributor of SOx and NOx due to its use of coal.

Our water business has grown significantly over

the recent years through acquisitions and organic

growth. We provide services ranging from specialised

industrial wastewater treatment to water reclamation,

desalination and the supply of potable and industrial

water. Sembcorp manages facilities capable of

producing and treating over seven million cubic

metres of water and wastewater daily and serves

over five million people worldwide. Through

innovation, we make every effort to ensure the

efficient use and reuse of water resources.

As part of the water solutions we offer to our

customers, we treat and supply water extracted

from surface water, groundwater (including lakes,

rivers, oceans and aquifers) as well as public utilities

(including wastewater). In 2011, our operations

in Singapore, China, the UAE, UK and Vietnam

extracted over 1,500 million cubic metres of water

primarily for treatment, supply to our customers

and use in our operations. Out of the total water

extracted, 91% was surface water, 4% was

groundwater, 3% was wastewater and 2% was

water from public utilities.

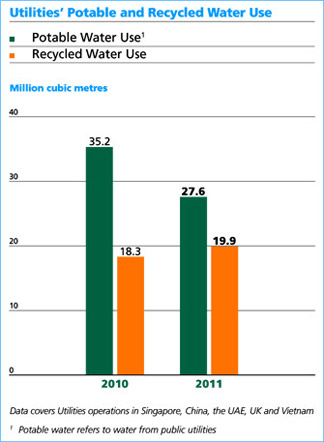

In 2011, Sembcorp recycled almost 20 million

cubic metres of water, or over 1% of our total

volume used, for supply to our customers and use

in our operations, reducing the intake of potable

or raw water supplies and also helping our customers

to reduce the amount of raw water needed for

their operations.

The graph below shows our potable water use

and the amount of water recycled.

Sembcorp received numerous awards in 2011

for its water services, including being named Water

Company of the Year at the prestigious Global Water

Intelligence’s Global Water Awards. This award

recognises Sembcorp as the water company that has

made “the most significant contribution to the

development of the international water sector in

2010”. Further information on the awards won by

Sembcorp in 2011 can be found here.

As one of the largest solid waste management

players in Singapore, Sembcorp provides services that

aim to reduce waste going to incineration or landfill

facilities. We also promote waste reduction by

encouraging recycling. In line with our business focus

to reduce waste for disposal, we are actively

developing differentiating know-how including

energy-from-waste capabilities. Our woodchip-fuelled

biomass steam production plant began full

commercial operations in late 2011, and is the first

such energy-from-waste facility in Singapore to

produce renewable process steam for third party

commercial customers on Jurong Island.

Our Group HSE guidelines require that any

uncontrolled and / or unauthorised discharge of

substances or any spill and / or leak of 500 litres or

more without secondary containment is reported.

There were no reportable spills or leaks in 2011.

An enhanced set of HSE reporting parameters

including the Sembcorp 4/0 targets was agreed upon

in February 2011 for application across all business

units in Singapore and overseas.

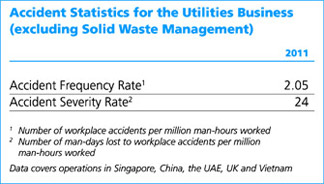

Using indicators of accident frequency rate (AFR)

and accident severity rate (ASR), in accordance with

the tracking criteria set by Singapore’s Ministry of

Manpower, the safety performance from our Utilities

operations in Singapore, China, the UAE, UK and

Vietnam has been recorded.

Our Utilities operations, excluding solid waste

management, reported 14 lost time injuries and

19 first aid cases in 2011, plus 166 man-days lost

in 2011 (0.01% of the total man-hours worked)

due to injuries sustained by our employees and

contractors during operations.

Our employees are monitored for noise induced

hearing loss and dermatitis and no case of either

incident was reported in 2011.

The solid waste management business’ safety

performance in Singapore is reported separately

from the performance of the rest of our Utilities

operations. This is due to the fact that the solid

waste management business’ waste collection

operations employ manual labour to a greater degree

and therefore have a different risk profile from our

energy, water and on-site logistics operations.

Our solid waste management business in

Singapore saw an increase in the AFR from 6.4 in

2010 to 10.6 in 2011. However, its ASR decreased

from 346.9 in 2010 to 148.3 in 2011. Safety remains

important to us and our solid waste management

business has taken preventive action to improve its

AFR and ASR levels. This includes ‘toolbox meetings’

with management and employees to cover the

importance of health and safety and spot inspections

at operational sites. In addition, monthly briefing

sessions are organised to allow employees to share

their lessons learnt in managing safety in their work.

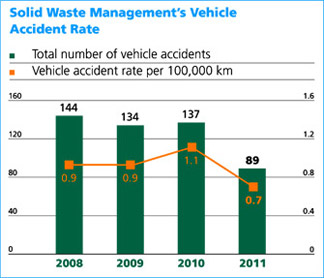

Sembcorp’s solid waste management business in Singapore operates a fleet of 200 commercial

vehicles and our staff undertake a considerable

amount of driving each year. One of our key safety

indicators for this business is vehicle accidents. In

2011, there was a substantial decrease in the

accident rate both in terms of absolute numbers

(89 in 2011 compared to 137 in 2010) and number

of incidents per 100,000 kilometres driven (0.7 in

2011 compared to 1.1 in 2010).

In January 2011, in addition to the stringent

selection process in the recruitment of drivers,

the company also commenced a safety training

programme for our waste collection truck drivers

in Singapore. This has improved their road safety

awareness and defensive driving ability to reduce

accident rates.

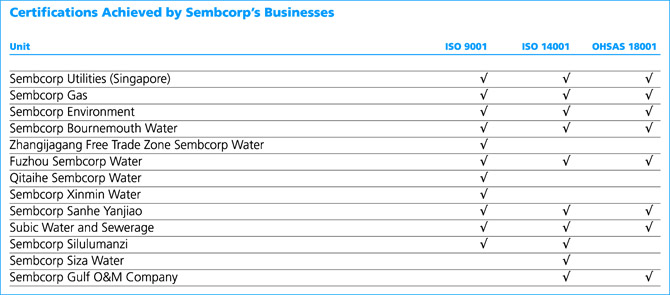

All our products and services are assessed

according to internationally recognised HSE and

quality management systems. HSE and quality

internal audits are conducted regularly to ensure

that the quality of our water supply meets legal and

product specifications. For the list of certifications

achieved by Sembcorp’s businesses, please click here.

At Sembcorp, we recognise that our employees

are our most valuable asset and a key stakeholder

group. We are committed to providing a fair, diverse and

inclusive workplace, and to continuous improvement in

our human resource and people development practices.

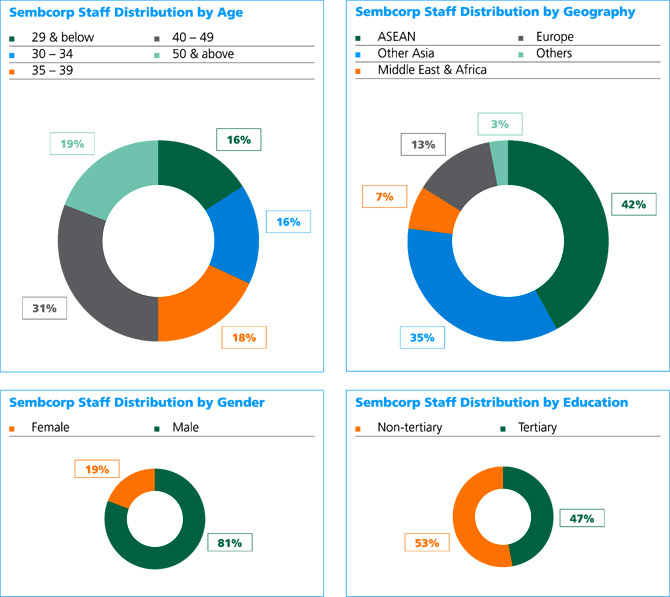

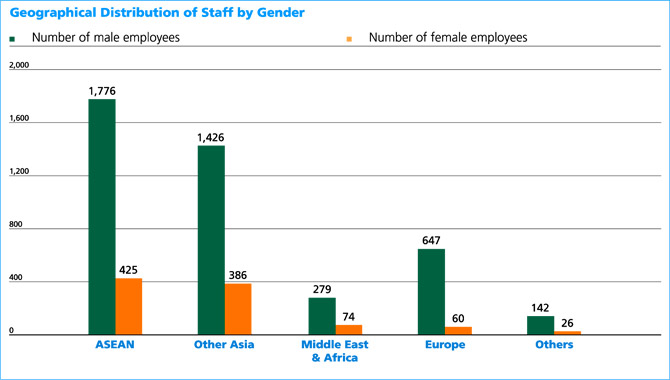

Sembcorp strives to maintain a fair, diverse and

inclusive workplace for all its employees. At the end of

2011, there were over 5,000 permanent employees in

the entire Sembcorp group, excluding employees from

the Marine business. 11% of our total headcount

were contract employees. Please see the charts below for the distribution of all Sembcorp’s

permanent employees, excluding employees from the

Marine business, by age, geographical region, gender

and education. Any deviation from this scope is noted

under the individual sections.

With our headquarters based in Singapore, the

Group subscribes to the Principles of Fair Employment

formulated by the Singapore Tripartite Alliance for Fair

Employment Practices and has endorsed the Tripartite

Alliance’s Employers’ Pledge of Fair Employment

Practices. These principles, embedded into our human

resource practices and implemented by Sembcorp on

a global level, include a commitment to:

| • |

Recruit and select based on merit, such as skills,

experience and ability, regardless of age, race,

gender or family status |

| • |

Treat employees fairly and with respect and

implement progressive human resource

management systems |

| • |

Provide equal opportunities for training and

development based on employees’ strengths and

needs, to help them achieve their full potential |

| • |

Reward fairly, based on ability, performance, contribution and experience |

| • |

Abide by labour laws and adopt tripartite guidelines which promote fair employment practices |

The significantly higher proportion of male

employees in Sembcorp’s headcount is consistent

with industry norms, where the nature of work

required in plants involves more physically demanding

tasks. Sembcorp ensures that equal opportunity is

given to all female employees across the Group.

The staff distribution of non-executive staff

by gender is 12% female and 88% male. The

distribution of staff by gender for executives is

28% female and 72% male.

Sembcorp fully supports the basic principles

of human rights and has implemented a number

of policies throughout the Group in support of these

principles, including fair employment practices and

a grievance and harassment policy.

A key tenet of Sembcorp’s business ethics is strict

respect for labour laws within each of the countries

we operate in, all of which preclude forced or child

labour, and is further supported through our policies

and employment practices. The technical nature of

our operations requires an experienced workforce,

both within the organisation and in our supply chain,

as specialist skills are required.

Sembcorp continues to promote a holistic and

balanced lifestyle for our employees, which we

believe is good for both their physical and mental

health. We encourage employees at our various

business units to participate in employee recreation

activities throughout the year, including community

outreach and volunteering initiatives, team sports

events, talks, gatherings and employee family days.

Some of these activities welcome employees to

participate with their family members, such as our

Sembcorp Family Day in Singapore and Fujairah.

Sembcorp also organises an annual Health

Week, a company-funded health education initiative

that helps equip employees in Singapore with

essential health knowledge and personal lifestyle skills.

We recognise the importance of engaging with

our employees and have various platforms through

which we communicate with and receive feedback

from our staff. We provide information on our financial

and business performance as well as on applicable

company standards and policies to our staff. Interactive

staff communication sessions with management are in

place to ensure two-way communication between the

company and its employees.

In 2011, we continued to hold employee briefing

sessions in conjunction with the company’s quarterly

financial reporting cycle. At these sessions, senior

management provides employees with information

on the company’s performance and key

developments. Presentations are also held to brief

employees on topics such as corporate social

responsibility or specific company policies such

as fraud management.

We continue to hold an annual communication

forum in Singapore for managers from Sembcorp

offices all over the world, with detailed briefings from

top management and external experts on our Group’s

operating environment, performance, outlook and

strategy. This forum incorporates an interactive

networking and question and answer session.

Furthermore, at the country level, some business

units also hold quarterly learning and sharing sessions,

senior manager briefings and staff consultation group

sessions. At Sembcorp Bournemouth Water in the UK,

there is also a staff consultative group made up

of elected staff representatives and management

representatives, which meets quarterly to discuss

relevant employee issues.

Over the course of the year, we continued to

communicate corporate updates and business

milestones to all staff through employee emails and

bi-monthly e-newsletters. Relevant and up-to-date

information on staff welfare and benefits was also

publicised to employees via the company intranet.

Sembcorp welcomes feedback from its employees

and provides confidential channels through which

employees can submit feedback and staff

suggestions, including an easily accessible online

channel on the employee intranet. All feedback is

sent to the Group Human Resource department and,

if sent via the internet, is also automatically copied to

the Senior Vice President of Group Human Resource

and the Group President & CEO’s office.

In line with our commitment to high ethical

standards and good corporate governance practices,

we have in place a group-wide whistle-blowing policy

and encourage all employees to report any possible

improprieties on a confidential basis without fear of

recrimination. We have an easily accessible whistle-blowing

link on our company intranet and employees

may also provide feedback via email, mail or fax.

Within the boundaries of each of the jurisdictions

under which we operate, Sembcorp employees are

entitled to practise freedom of association in the

workplace. Sembcorp’s operations span six

continents where labour relations, regulations and

practices differ widely. In 2011, 42% of Sembcorp’s

employees were union members.

Sembcorp maintains excellent labour

management relations with its unions, and holds

constructive ongoing exchanges with employee

unions in its various locations. In Singapore,

Sembcorp is committed to working closely with

the Building Construction and Timber Industries

Employees Union (BATU) as well as the Union

of Power and Gas Employees (UPAGE). Our re-employment

policy, endorsed by BATU and UPAGE,

gives medically fit employees the option of

continuing on their jobs beyond the statutory

retirement age. In an event organised by BATU and

Sembcorp, the Prime Minister of Singapore visited

our Bukit Merah Depot on the first day of Lunar New

Year in 2011 to show appreciation to the workers

who continued to work tirelessly and perform vital

duties on this public holiday.

In the UK, Sembcorp Bournemouth Water has a

long standing relationship with its recognised unions

GMB and Unison. Both unions sit on Sembcorp’s staff

consultative group and the health and safety

committee, where they also participate in safety

inspections. At our Teesside operations, discussions

with Unite (the UK’s biggest union) are conducted in

line with our collective ‘Together Agreement’ which

covers over 90% of our employees at this operation.

Formal joint consultation meetings with employees

and unions are conducted three times a year, and

meetings between management and the company’s

senior union representatives are held bi-monthly.

Sembcorp’s success is driven by the calibre and

performance of its people. We recognise that it is

essential to equip our employees across all levels of

seniority to meet the changing needs of the

marketplace. Sembcorp offers employees a range of

personal and professional development opportunities

including career development, education, talent

management and leadership programmes.

In 2011, the Group continued to invest in

competency building for our employees, spending

over S$1.5 million on training for employees within

our operations in Singapore, China, the UAE and UK.

It is a priority for us to enhance the skill level

of our employees to ensure smooth succession.

Sembcorp’s learning and development programmes

factor in issues such as succession planning and

addressing skill gaps with relation to core

competency requirements.

Around 5% of our non-executive staff worldwide

are due to retire in the next five years, and a further

7% in the next six to 10 years. Around 2% of our

executive staff worldwide are due to retire in the next

five years, and a further 5% in the next six to 10 years.

The Sembcorp Leadership Competencies

programme is our unique talent management and

development system that defines the qualities and

performance expectations of a Sembcorp leader.

Capable leaders are crucial in achieving business

success and the Sembcorp Leadership Competencies

detail the ways in which Sembcorp leaders should

act and respond. Managers also attend courses

to enhance their presentation, negotiation,

communication and coaching skills as well as

courses on building and leading high-performance

teams. Senior executives are expected to undertake

regular training to update and upgrade their

skills and education programmes are accessible to

them at prestigious institutes such as the Harvard

Business School, INSEAD and the Temasek Business

Leadership Centre.

We offer employees the opportunity to

experience different cultural and operational settings

through job rotations and attachments. We currently

have more than 50 employees of different

nationalities posted from our Singapore office to

various overseas businesses. Internships and industrial

attachments also provide students and Sembcorp

scholars with practical experience and exposure to

our operations while they undergo their studies.

We send our employees for professional training

to allow them to develop skill sets that better equip

them for their roles. Working with local educational

institutions in Singapore, we send our engineers to

specialised technical competency courses. Our

employees are also sent for professional training

related to the industry, including courses under

Singapore’s National Skills Recognition Scheme and

Workforce Skills Qualification scheme under the

Workforce Development Authority.

In Singapore, staff are also encouraged to

pursue higher qualifications which are sponsored

by the company.

In the UK, our operations are signed up to the

‘Investors in People’ standard, the UK’s leading people

management standard. This provides a business

improvement tool to help organisations develop

performance through their people. Both our operations aim to provide education and training

for all employees to carry out their duties and provide

them with appropriate opportunities for development.

This involves identifying skill gaps in accordance with

core competencies. Sembcorp is also helping to shape

the future of the industry by proactively engaging in

training and skills development throughout the

northeastern region, as well as raise the performance

bar of apprentices and other workers in the industry.

As an industry leader in various sectors,

Sembcorp encourages our employees to share

and exchange best practices through platforms

such as seminars and conferences on a local

and international basis. In the UK, our Senior Vice

President of Regional Human Resource sits as the

Chairman of the North East Regional Skills Board for

the National Skills Academy for the Process Industries

and uses his expertise to improve the skills of the

existing workforce as well as attract and retain new

entrants to the industry.

Sembcorp has implemented a system for

performance appraisals across its operations in all

countries. The appraisal system allows all employees

to comment on their personal contribution

throughout the year and to jointly identify areas for

further career development and learning with their

supervisors on a regular basis. It enables constructive

discussion and uses the feedback process to ensure

that employees share the responsibility for managing

their career and goals. The appraisal process

incorporates shared future objectives to ensure that

employee outputs are also aligned to the needs of

the business. Selected senior managers are also

assessed using a 360-degree appraisal system where

feedback is sought from a range of superiors, peers

and colleagues and other partners. The profile of

essential competencies for the job function compiled

from this process is also incorporated into these

managers’ development plans, helping them lead

their teams successfully and enhance their

professional performance.

Rewarding performance is the key component

of Sembcorp’s employment retention strategy.

The Group offers competitive base pay packages

throughout our global businesses that are based on

country-specific conditions. Rewards include annual

salary increments and annual performance bonuses,

as well as longer-term incentives linked to sector

practices and based on the performance of the

Group, the company and the individual.

Share-based incentives, administered by a board

nominated committee, remain a key component

of the Group’s pay structure and are deliberately

aligned to long-term Group performance objectives.

Since 2007, share options granted to staff have been

replaced with restricted shares. This Restricted Share

Plan applies to employees of the Group, while the

Performance Share Plan is primarily for key executives

of the Group.

All employees are eligible for comprehensive

insurance coverage on a global basis. They can join

the company’s private medical and dental insurance

scheme under which the company meets the cost of

employee membership and allows employees to

include eligible dependants. The company also

provides additional insurance cover for life, travel,

personal accidents, workers’ compensation and

hospitalisation and surgical expenses.

Sembcorp maintains an ongoing commitment

to support the local communities in which we

operate through supporting social development and

community investment projects. In 2011, Sembcorp

contributed over S$1.3 million in cash and in-kind

support to its communities (excluding community

investment initiatives by our separately listed Marine

business). We took part in many initiatives in our communities in support of children and the elderly,

education, the environment and sports and fitness.

Our employees are active volunteers in the

community, providing helping hands as well as

management expertise. 48% of our operations

have local community engagements and

development programmes.

Our employees offer their time to volunteer in

a number of initiatives that the company organises.

For example:

| • |

Sembcorp has been a supporter of Singapore’s

Assisi Hospice (which provides palliative care for

people with life-limiting illnesses) since 2008.

Sembcorp volunteers help with the running of

the charity’s Fun Carnival, which generated more

than S$800,000 in donations in 2011, as well as

its Christmas carnival, bringing goodwill and

cheer to the patients. |

| • |

For the third year running, Sembcorp has

partnered with the Sunshine Welfare Action

Mission (SWAMI) in Singapore to bring festive

cheer to needy elderly households. SWAMI is a

non-profit organisation providing nursing care

and shelter for the sick, aged and handicapped

from needy backgrounds. In the run-up to the

Lunar New Year in 2011, SWAMI identified 23

households whose residents do not have the ease

of movement, to benefit from volunteers spring

cleaning their homes. |

| • |

In the UK, Sembcorp employee Jane Atkinson

was granted an honorary doctorate in Business

Administration by Teesside University, one of the

leading UK universities for engineering, in

recognition of her work in championing

engineering education among youths. |

Sembcorp supports projects that help

communities, such as:

| • |

In 2011, Sembcorp, through its joint venture

in the Vietnam Singapore Industrial Park,

launched the first community clinic in Binh

Duong. With a medical team from My Phuoc

Hospital, this clinic provides free first aid,

medical consultation and counselling services

for the medically underserved populations

of Binh Duong province. |

| • |

In China, our Yancheng operations organised

their fifth ‘Water Services For The Community’

event in the Chaoyang district to promote the

accessibility of municipal water for all. The event

helped facilitate water maintenance and repair

services for the residents, and also generated

greater awareness on water conservation, quality

and pricing. |

| • |

In South Africa, Sembcorp Siza Water donated

an immune haematology test machine to a local

non-governmental organisation HIV / AIDS centre

to help overcome traveling and cost barriers

to getting tested. |

| • |

Sembcorp Bournemouth Water has been a

supporter of international charity WaterAid. In

2011, Sembcorp Bournemouth Water received

The President’s Award, endorsed by WaterAid’s

President, His Royal Highness The Prince of Wales,

for its support over the last 30 years. |

| • |

Our operations in Teesside extended their

professional expertise to a neighbouring village

to help secure lower costs with the building

suppliers for the renovations of their historic

village hall. |

| • |

Sembcorp Utilities Chile worked with local

community leaders to pilot a campaign in two

Santiago regions, entitled ‘Yo cuido mi grifo’ (I take care of my fire hydrant), to educate the

local community about the importance of fire

hydrants. The project also saw the opening of

two children’s water parks. The project resulted in

savings of over 600,000 litres of water a day. |

Sembcorp also contributes to programmes

supporting wildlife and biodiversity. We continue

to support the Sembcorp Forest of Giants in the

Southern Ridges through donations to the Singapore

National Parks Board’s registered charity, the Garden

City Fund. In 2011, we further developed the

programme to promote greater awareness and

appreciation of nature. Sembcorp volunteers were

trained to be guides of the Southern Ridges, which

span the hills of Mount Faber Park in Singapore.

Sembcorp’s municipal water operations in

Bournemouth, UK, continues its long-standing

support of the Dorset Wildlife Trust which manages

more than 40 nature reserves in the county. In 2011,

Sembcorp Bournemouth Water provided support to

the charity to restore areas of chalk streams that have

been affected by human intervention. The crystal

clear waters of chalk streams support more wildlife

than any other waters in Britain, with a huge range

of aquatic insects, spawning sites for trout and

salmon and food for predators.

For further information on sustainability at Sembcorp Industries, please visit our website at www.sembcorp.com. If you have any comments or wish to discuss any of the contents of this report or other sustainability issues, please contact:

Group Corporate Relations

Tel: +65 6723 3113

Email: [email protected] |

| |

|

|

|

|