- BUILDING THE FUTURE

- OPERATING & FINANCIAL REVIEW

- GOVERNANCE & SUSTAINABILITY

- FINANCIAL STATEMENTS

- Directors’ Statement

- Independent Auditors’ Report

- Balance Sheets

- Consolidated Income Statement

- Consolidated Statement of

Comprehensive Income - Consolidated Statement of

Changes in Equity - Consolidated Statement of

Cash Flows - Notes to the Financial Statements

- Supplementary Information

- EVA Statement

- Shareholders' Information

- Governance Disclosure Guide

- Corporate Information

- Notice of Annual General Meeting

- Proxy Form

- Letter to Shareholders

SUSTAINABILITY REPORT

Sustainability at Sembcorp is about striving for excellence and continuous improvement in identifying, understanding and responding to evolving environmental, social and governance challenges facing our businesses.

MANAGING SUSTAINABILITY

At Sembcorp, we believe in building sustainable businesses that deliver long-term shareholder value and growth. We believe that a truly sustainable business not only creates economic value, but does so in a way that benefits its stakeholders.

Environmental, social and governance (ESG) considerations are embedded in our business decisions and processes. We believe that taking ESG considerations into account helps us understand our risks and responsibilities in a holistic manner. We also believe that when our strategy and business decisions incorporate ESG concerns, we are better prepared to respond to the challenges we face.

The management of our sustainability issues is centred on five focus areas. Our key sustainability principles are set out in our Sustainability Policy. These principles are applied throughout our management systems and processes. We aim to continually improve our management systems, and evaluate our management approach by benchmarking it against industry best practice. We adopt a precautionary approach to avoid or minimise negative impacts. A list of our policies, certified facilities as well as memberships and participation in external initiatives can be found in the Sustainability section of our website.

Sustainability is addressed at the highest levels at Sembcorp. Our Board of Directors oversees the business affairs of the Group and is collectively responsible for our long-term success. The main duties of the board include providing leadership on Sembcorp’s overall strategy, which takes into consideration sustainability issues. The board also ensures the adequacy of the Group’s framework for risk management and internal controls.

Sembcorp’s Sustainability Steering Committee (SSC) provides strategic direction for managing sustainability-related risks and opportunities. It also guides the development and improvement of frameworks, policies, guidelines and processes to ensure that sustainability issues are effectively managed. The SSC is a high-level committee chaired by the Group Chief Financial Officer, and comprises senior executives across various functions, including asset management, human resources, health, safety and environment (HSE) and corporate relations.

At the business unit level, economic, operational, as well as health and safety issues and other risks are reviewed by the head of operations at bi-monthly business unit management meetings and risk management committee meetings. The Group’s performance in these areas is evaluated against internal targets. Business units also provide quarterly governance assurance certifications on the adequacy of their risk management and internal control systems in line with Sembcorp’s Governance Assurance Framework (GAF).

Sustainability contact

Sembcorp welcomes feedback on our sustainability issues and reporting at [email protected].

Sustainability Performance SnapshotEnvironmental, social and governance (ESG) considerations are embedded in our business decisions and processes. We believe that taking ESG considerations into account helps us understand our risks and responsibilities in a holistic manner. We also believe that when our strategy and business decisions incorporate ESG concerns, we are better prepared to respond to the challenges we face.

The management of our sustainability issues is centred on five focus areas. Our key sustainability principles are set out in our Sustainability Policy. These principles are applied throughout our management systems and processes. We aim to continually improve our management systems, and evaluate our management approach by benchmarking it against industry best practice. We adopt a precautionary approach to avoid or minimise negative impacts. A list of our policies, certified facilities as well as memberships and participation in external initiatives can be found in the Sustainability section of our website.

Sustainability is addressed at the highest levels at Sembcorp. Our Board of Directors oversees the business affairs of the Group and is collectively responsible for our long-term success. The main duties of the board include providing leadership on Sembcorp’s overall strategy, which takes into consideration sustainability issues. The board also ensures the adequacy of the Group’s framework for risk management and internal controls.

Sembcorp’s Sustainability Steering Committee (SSC) provides strategic direction for managing sustainability-related risks and opportunities. It also guides the development and improvement of frameworks, policies, guidelines and processes to ensure that sustainability issues are effectively managed. The SSC is a high-level committee chaired by the Group Chief Financial Officer, and comprises senior executives across various functions, including asset management, human resources, health, safety and environment (HSE) and corporate relations.

At the business unit level, economic, operational, as well as health and safety issues and other risks are reviewed by the head of operations at bi-monthly business unit management meetings and risk management committee meetings. The Group’s performance in these areas is evaluated against internal targets. Business units also provide quarterly governance assurance certifications on the adequacy of their risk management and internal control systems in line with Sembcorp’s Governance Assurance Framework (GAF).

In 2015, Sembcorp became a signatory to the United Nations (UN) Global Compact, joining more than 8,000 companies globally who have taken a stand for a sustainable future.

Sembcorp was also selected as an index component of the Dow Jones Sustainability Asia / Pacific Index 2015.

Sembcorp was also selected as an index component of the Dow Jones Sustainability Asia / Pacific Index 2015.

Sustainability contact

Sembcorp welcomes feedback on our sustainability issues and reporting at [email protected].

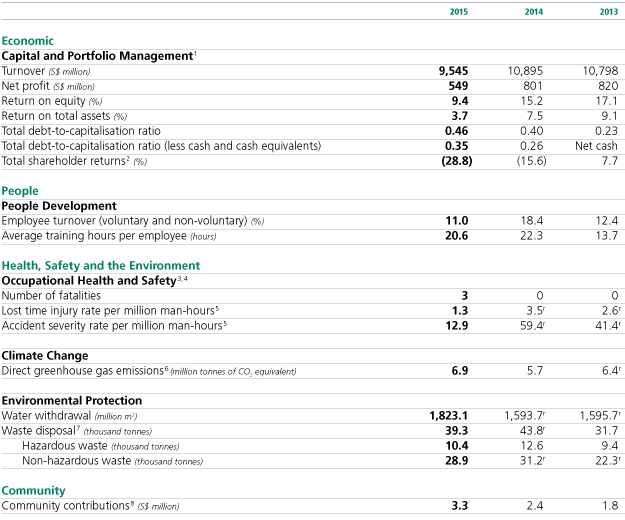

The table below shows quantitative data that reflects our performance in areas that have been identified as material to our businesses and stakeholders.

Notes:

Please refer to the section on Reporting Framework and Scope for details on our scope.

More performance data, including qualitative data, is available in the individual sections for each focus area in this report, as well as in the Sustainability section of our website.

Materiality

Notes:

Please refer to the section on Reporting Framework and Scope for details on our scope.

| 1 | Financial figures reported are for the Group, including Sembcorp Marine, as per audited financial statements. |

| 2 | Source: Bloomberg |

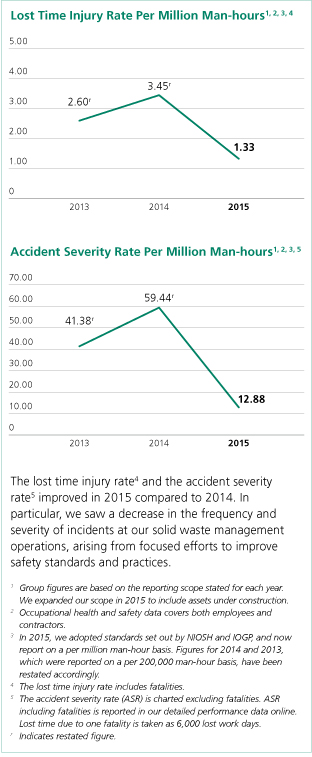

| 3 | Health and safety data reflects group-wide performance within the reporting scope stated for each respective year. For 2015, it covers both assets in operation and under construction. A detailed breakdown of health and safety data is available on our website. |

| 4 | Data covers employees and contractors engaged to work on our sites. Details of fatalities are reported here. |

| 5 | In 2015, we adopted standards set out by the US National Institute for Occupational Safety and Health (NIOSH) and the International Association of Oil and Gas Producers (IOGP), and now report on a per million man-hour basis. Figures for 2014 and 2013, which were reported on a per 200,000 man-hour basis have been restated accordingly. |

| 6 | Data covers operations that produce direct greenhouse gas emissions from the combustion of fossil fuel. |

| 7 | Data for waste disposal excludes waste that is collected and incinerated for our customers. |

| 8 | Figure excludes contributions from Sembcorp Marine. Including contributions from Sembcorp Marine, the Sembcorp Group’s contributions amounted to S$7.1 million. |

| r | Indicates restated figure. Details can be found in the respective sections of this Sustainability Report and the Global Reporting Initiative content index in the Sustainability section of our website. |

More performance data, including qualitative data, is available in the individual sections for each focus area in this report, as well as in the Sustainability section of our website.

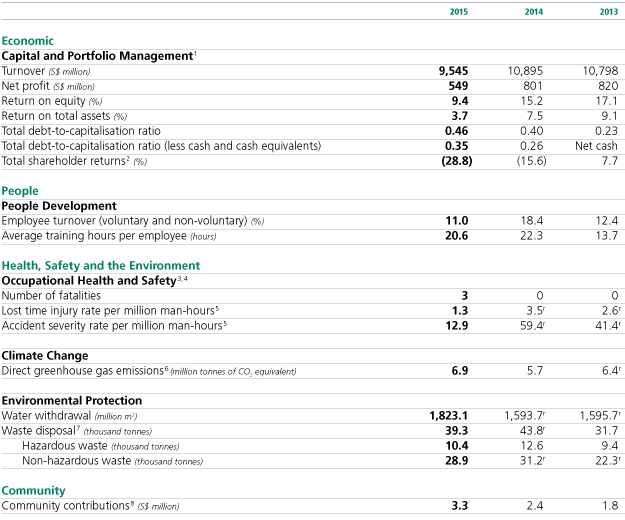

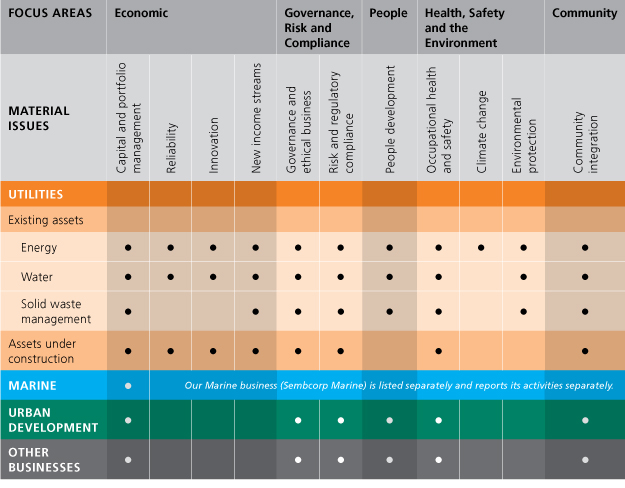

Materiality analysis enables Sembcorp to define sustainability issues that are of greatest significance to our businesses and stakeholders over the long term. As we seek to make progress in our sustainability journey, drive performance and transparency, and embed sustainability into Sembcorp’s culture, this focus on materiality is vital.

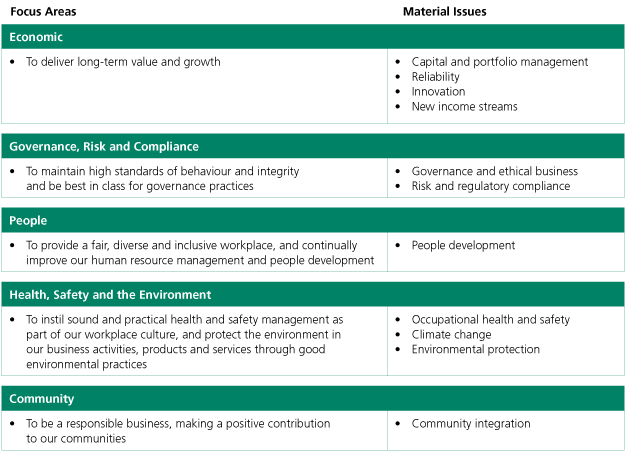

Our reporting is currently focused on 11 material issues, grouped into five focus areas. Each focus area is owned by an appointed SSC member. The five focus areas and 11 material issues are recognised by both internal and external stakeholders. For each material issue, we report the sustainability context, its relevance to Sembcorp, and our management approach and performance.

Sustainability issues were identified in line with Global Reporting Initiative (GRI) guidelines. The materiality review took into account GRI’s Electric Utilities Sector Supplement, the Dow Jones Sustainability Index and other relevant frameworks and peer reviews. We prioritised issues using a materiality matrix, taking into account their significance to Sembcorp and our stakeholders according to clearly defined criteria based on the AA1000AS five-part materiality process.

The materiality assessment and review were conducted with input from an independent sustainability consultant. To increase the robustness of this assessment, we incorporated feedback from our stakeholders, including shareholders, financial institutions, the investment community, regulators, customers, suppliers and non-governmental organisations. The survey, commissioned in 2012, was conducted by an independent firm to ensure anonymity for respondents. On the whole, respondents agreed on where our focus should lie. Their responses also helped us refine aspects of the material issues that our key stakeholders were interested in, and provided input on how we could better communicate these issues.

Sembcorp embarked on reviewing and updating our materiality issues in late 2015. As part of this materiality review process, we will be undertaking a stakeholder engagement survey, and gathering input from internal and external stakeholders across our different business units globally and at the corporate level. We will review and use the information we gather from our stakeholders to refresh our material issues and ensure that Sembcorp continues to align our sustainability efforts with business growth. The results of this materiality review and the corresponding updates to our material issues and indicators will be presented in our 2016 report.

In 2015, we strengthened the link between risk management and sustainability at Sembcorp, by developing risk appetite statements for each of our sustainability focus areas. The risk appetite statements and associated key risk indicators set the direction and boundaries for the execution of our strategy, and provide early warning of increasing risk exposure in each focus area.

Sembcorp’s Materiality MatrixOur reporting is currently focused on 11 material issues, grouped into five focus areas. Each focus area is owned by an appointed SSC member. The five focus areas and 11 material issues are recognised by both internal and external stakeholders. For each material issue, we report the sustainability context, its relevance to Sembcorp, and our management approach and performance.

Sustainability issues were identified in line with Global Reporting Initiative (GRI) guidelines. The materiality review took into account GRI’s Electric Utilities Sector Supplement, the Dow Jones Sustainability Index and other relevant frameworks and peer reviews. We prioritised issues using a materiality matrix, taking into account their significance to Sembcorp and our stakeholders according to clearly defined criteria based on the AA1000AS five-part materiality process.

The materiality assessment and review were conducted with input from an independent sustainability consultant. To increase the robustness of this assessment, we incorporated feedback from our stakeholders, including shareholders, financial institutions, the investment community, regulators, customers, suppliers and non-governmental organisations. The survey, commissioned in 2012, was conducted by an independent firm to ensure anonymity for respondents. On the whole, respondents agreed on where our focus should lie. Their responses also helped us refine aspects of the material issues that our key stakeholders were interested in, and provided input on how we could better communicate these issues.

Sembcorp embarked on reviewing and updating our materiality issues in late 2015. As part of this materiality review process, we will be undertaking a stakeholder engagement survey, and gathering input from internal and external stakeholders across our different business units globally and at the corporate level. We will review and use the information we gather from our stakeholders to refresh our material issues and ensure that Sembcorp continues to align our sustainability efforts with business growth. The results of this materiality review and the corresponding updates to our material issues and indicators will be presented in our 2016 report.

In 2015, we strengthened the link between risk management and sustainability at Sembcorp, by developing risk appetite statements for each of our sustainability focus areas. The risk appetite statements and associated key risk indicators set the direction and boundaries for the execution of our strategy, and provide early warning of increasing risk exposure in each focus area.

Reporting framework and scope

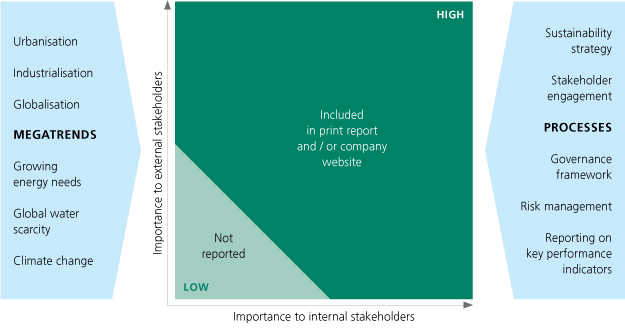

Our annual Sustainability Report is prepared in accordance with GRI G4 Core requirements. It is guided by SGX Guidelines on Sustainability Reporting as well as the Ten Principles of the UN Global Compact. Our GRI content index can be found in the sustainability section of our website.

Our report provides information on Sembcorp’s subsidiaries and covers the calendar year. It excludes joint ventures, partnerships and associates for which Sembcorp does not have management and / or operational control. As our Marine business is separately listed in Singapore and reports its activities separately, it is therefore excluded from this report. New acquisitions and subsidiaries are given one year or more upon the completion of construction or agreement to integrate their reporting systems with that of the Group. Thereafter, their sustainability data will be reported externally once a full calendar year of data is collected. Data pertaining to entities divested during the year is excluded from our report. This year, we expanded the scope of our occupational health and safety reporting to also include assets and projects under construction, with data reported from the onset of construction activities. We aim to work towards external assurance of the report.

The table below shows our reporting scope by business line and focus area.

Information provided in the Sustainability Report relates to the subsidiaries of Sembcorp, excluding Sembcorp Marine. It excludes joint ventures, partnerships and associates for which Sembcorp does not have management and / or operational control.

Information provided in the Sustainability Report relates to the subsidiaries of Sembcorp, excluding Sembcorp Marine. It excludes joint ventures, partnerships and associates for which Sembcorp does not have management and / or operational control.

Data measurement and quality

All data measurements are in line with GRI G4 recommendations for our chosen indicators. Greenhouse gas (GHG) emission factors are based on the 2006 Intergovernmental Panel for Climate Change (IPCC) guidelines, except for those relating to our operations on Teesside, UK, which use emission factors adapted from the US Environmental Protection Agency and the 2013 and 2014 Government Greenhouse Gas Conversion Factors for Company Reporting issued by the UK’s Department for Environment, Food & Rural Affairs and Department of Energy & Climate Change. Occupational health and safety indicators follow standards set out by the US National Institute for Occupational Safety and Health (NIOSH) and the International Association of Oil and Gas Producers (IOGP).

While there are inherent limitations to the accuracy of data, we seek to minimise any errors and irregularities by strengthening our internal controls.

Sembcorp manages sustainability through five areas of focus. These focus areas are aligned with how we drive success for the Group. Under each focus area, we discuss our management approach to the relevant material issues and our performance against each issue.

MATERIAL ISSUES

We recognise the importance of building relationships and communicating openly with our stakeholders.

We identified our stakeholder groups following a stakeholder mapping exercise, done in accordance with the AA1000 Stakeholder Engagement Standard by an independent consultant in 2012. Using a structured approach, stakeholders were mapped based on their level of influence and interest. The level of stakeholder interest against each material issue was also reviewed and a survey was conducted to invite feedback on our material issues from selected key stakeholder groups. This allowed us to understand the concerns and perspectives of our external stakeholders in relation to our material issues, in order to formulate our sustainability priorities. It also helped to guide our communication to stakeholders on our performance and progress on our material issues.

More information on the platforms we use to regularly engage our stakeholders can be found in the Sustainability section of our website.

We identified our stakeholder groups following a stakeholder mapping exercise, done in accordance with the AA1000 Stakeholder Engagement Standard by an independent consultant in 2012. Using a structured approach, stakeholders were mapped based on their level of influence and interest. The level of stakeholder interest against each material issue was also reviewed and a survey was conducted to invite feedback on our material issues from selected key stakeholder groups. This allowed us to understand the concerns and perspectives of our external stakeholders in relation to our material issues, in order to formulate our sustainability priorities. It also helped to guide our communication to stakeholders on our performance and progress on our material issues.

More information on the platforms we use to regularly engage our stakeholders can be found in the Sustainability section of our website.

CASE STUDY

Working together to respond to

a drought crisis: Sembcorp Siza Water

As a result of El Niño, South Africa is facing one of its worst droughts in 30 years. The drought, which began in late 2014, has been declared a crisis by the government. Amongst the worst-hit areas in the country is the Dolphin Coast, where our municipal water business Sembcorp Siza Water operates.

As the local water provider, Sembcorp Siza Water has played a key role in managing the impact of the drought from an early stage. When the drought hit, it became apparent that it would be impossible for the conventional water system to be fully operational. Sembcorp Siza Water worked out a drought plan with local authorities and the bulk water supplier, and rolled this out to the community through an intensive communications campaign. Through daily slots on local radio, regular updates in newspapers and on the company website, flyers and text message alerts, we educated consumers on the crisis, called for support for the drought plan and communicated tips on how to save water. We also met key stakeholders face-to-face, including local councillors and authorities, as well as the ratepayers’ association, chamber of commerce and local business leaders, and held media interviews and briefings. The response to these measures led to the community reducing its water usage by 5,000 cubic metres per day.

In the course of engaging consumers and local councillors, the need to find innovative solutions to the water crisis was raised. Arising from this, we commissioned boreholes to augment water supply. In addition, we conducted a month-long online survey, during which 96% of consumers voted in favour of introducing recycled water to their potable water. We then completed a facility that reclaims potable water from effluent, increasing the water supply by 4,000 cubic metres. This has been a great success, eliminating the need for water shedding in the community.

This experience demonstrates that technical expertise is only part of the solution. To change public behaviour and generate sustainable solutions, engagement and partnership with stakeholders is also key.

As a result of El Niño, South Africa is facing one of its worst droughts in 30 years. The drought, which began in late 2014, has been declared a crisis by the government. Amongst the worst-hit areas in the country is the Dolphin Coast, where our municipal water business Sembcorp Siza Water operates.

As the local water provider, Sembcorp Siza Water has played a key role in managing the impact of the drought from an early stage. When the drought hit, it became apparent that it would be impossible for the conventional water system to be fully operational. Sembcorp Siza Water worked out a drought plan with local authorities and the bulk water supplier, and rolled this out to the community through an intensive communications campaign. Through daily slots on local radio, regular updates in newspapers and on the company website, flyers and text message alerts, we educated consumers on the crisis, called for support for the drought plan and communicated tips on how to save water. We also met key stakeholders face-to-face, including local councillors and authorities, as well as the ratepayers’ association, chamber of commerce and local business leaders, and held media interviews and briefings. The response to these measures led to the community reducing its water usage by 5,000 cubic metres per day.

In the course of engaging consumers and local councillors, the need to find innovative solutions to the water crisis was raised. Arising from this, we commissioned boreholes to augment water supply. In addition, we conducted a month-long online survey, during which 96% of consumers voted in favour of introducing recycled water to their potable water. We then completed a facility that reclaims potable water from effluent, increasing the water supply by 4,000 cubic metres. This has been a great success, eliminating the need for water shedding in the community.

This experience demonstrates that technical expertise is only part of the solution. To change public behaviour and generate sustainable solutions, engagement and partnership with stakeholders is also key.

Economic

To deliver long-term value and growth

Why this is material

Long-term economic viability is at the core of Sembcorp’s approach to building sustainable businesses. As we build successful, sustainable businesses, societies and communities benefit. Our businesses deliver the economic engine to support industrialisation and urbanisation. Our operations generate employment, contracts for local suppliers and tax revenues for governments and result in infrastructure development in our host communities. For more information on our contributions to communities, please refer to the Community section of this report. We drive our economic sustainability by monitoring and managing four key facets of our business: capital and portfolio management, reliability of our assets, products and services, innovation and business development for new income streams.

Capital and portfolio management

Sembcorp’s businesses often involve large-scale, long-term projects that require significant initial capital outlay. Strong financial health and a disciplined approach to investment are therefore necessary for us to succeed. At the same time, as Sembcorp continues to grow, we believe it is important for us to maintain a balanced portfolio of businesses across geographical regions and business segments, with the appropriate level of risk. Capital allocation, including the geographical distribution of our investments, is managed from this perspective.

Reliability

The reliability of our supply, assets and products is vital not only for our reputation, but also for our long-term profitability. Our Group is heavily invested in the Utilities business, which involves the development and sustained operation of energy and water facilities. We are committed to long-term customer contracts and our products and services, such as power, steam, water and wastewater treatment, are essential to our customers. By investing in the proper care and maintenance of our assets, we ensure that their useful life, and therefore their ability to generate stable recurring income and a reliable supply of products and services, is sustained throughout our long investment horizon.

Innovation

We recognise that technology and innovation is important in maintaining and enhancing our relevance, profitability and competitive advantage. This includes applied research and development (R&D) and improvements that optimise our operations and enhance our efficiency, as well as new technologies and methodologies that offer wider sustainability benefits.

New income streams

To deliver long-term growth, we continuously explore new business opportunities and maintain a pipeline of upcoming projects, which includes both greenfield and brownfield investments.

Our approach

Capital and portfolio management

We have robust frameworks and processes in place to ensure our investment and business decisions take into account long-term considerations. In addition, potential acquisitions and growth opportunities are evaluated based on strict investment guidelines. Depending on criteria such as project value and country risk, approval for projects may involve the Senior Management Committee, the board and / or its Executive or Risk Committee.

We actively manage our risk portfolio, including monitoring balance sheet liquidity ratios and country risk profiles. For more information on risk management at Sembcorp, please refer to the Risk Management and Internal Controls chapter.

Reliability

Reliability of our assets, products and services

The reliability of our assets is of critical importance, and is rigorously managed from the design phase through to the operation and maintenance phase. In the design and construction phases, we focus on installing sufficient operational flexibility and selecting quality equipment. In the operation and maintenance phases, regulatory and manufacturers’ standards are strictly adhered to. The reliability of our plants is further monitored through monthly performance indicators which our management oversees. Technical audits and checks are also conducted on our plants.

Product safety and compliance

Product safety is a priority in our business, as non-compliance can result in serious health, safety and operational issues for our customers, many of whom depend on us for basic utilities or require our products for their industrial processes. We implement a robust maintenance and monitoring regime, which includes stringent inspections and the installation of meters and sensors at both our and our customers’ facilities. To ensure the safe delivery of our products, we have rigorous maintenance regimes in place and regularly inspect our delivery systems, including checking pipelines for leaks. We also conduct regular sampling and laboratory tests to meet regulatory requirements and to ensure that the water we produce is safe for our customers and end users.

Innovation

Sembcorp’s Technology Advisory Panel, which includes our Chairman, Group President & CEO and other invited experts, provides strategic direction for our technology and innovation programmes. The panel oversees the development and application of significant emerging technologies in the energy and water sectors and provides guidance to Sembcorp’s leadership on technological trends and opportunities. It is supported by an in-house Group Technology department.

Headed by our Chief Technology Officer, our Group Technology department oversees our R&D and innovation efforts. Besides tracking our investment in innovation and its corresponding returns, we also track indicators such as the number of projects screened. This ensures that we have a pipeline of innovation projects being developed and implemented in a timely manner.

To further encourage innovation from bottom up, Sembcorp’s !DEA Awards programme rewards innovative ideas and efforts across the Group. Past winning entries have included process innovations that have resulted in cost savings and improved HSE performance, as well as innovations that have led to the development of new products and services.

Our ongoing engagement with venture capitalists, technology companies and tertiary research institutes helps us keep abreast of the latest technological advancements. In looking at new technology, we prioritise innovations that address the needs of our operations, but also consider more general proposals.

New income streams

Sembcorp’s Group Business Development & Commercial department is structured and equipped to pursue new business opportunities with agility and focus. Dedicated teams look into growing our businesses in both existing and new markets.

To ensure our continued growth, we identify and develop a healthy pipeline of projects. We also seek to grow through strategic partnerships with our customers, by continuously developing innovative and competitive solutions that meet their evolving needs.

We actively invest in sustainable and green business lines, which will give us an edge in an increasingly resource-scarce world. We take a disciplined approach and employ a stringent evaluation process to all our projects and investments.

Our performance

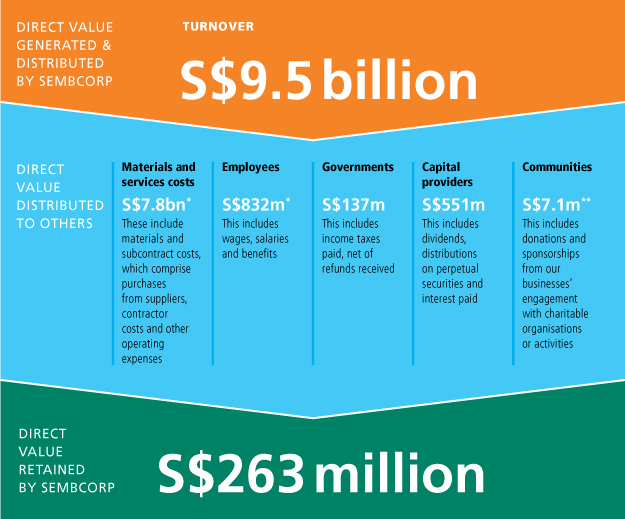

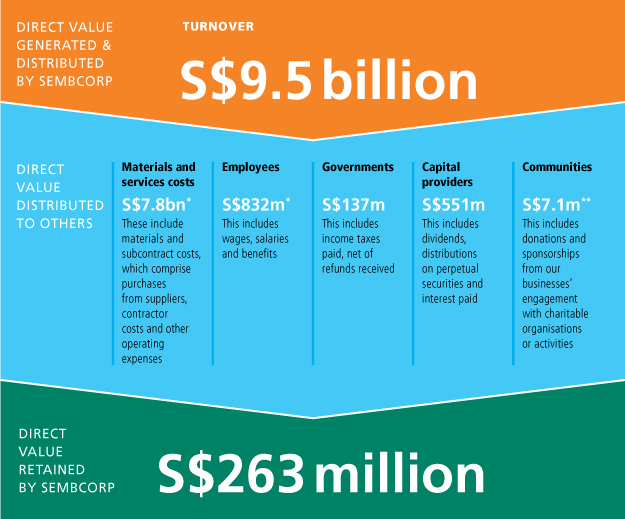

Sembcorp’s financial performance and key economic indicators can be found in our Group Financial Review chapter and Financial Statements.

As a global energy and water company with a rich history of being driven by technology and innovation, Sembcorp hopes to contribute towards raising Singapore’s profile as a hub for applied R&D, while supporting the long-term growth of the energy and water sectors. To this end, we have collaborated with several partners in various innovation projects. Ongoing partnerships include the Sembcorp Industrial Living Laboratory with the Singapore Economic Development Board and the Sembcorp-EMA Energy Technology Partnership with the Energy Market Authority (EMA) of Singapore. These projects leverage Sembcorp’s facilities for late-stage test-bedding and co-innovation of energy, water and environmental technologies, and explore the commercialisation of R&D solutions. The investments in these multi-year projects, which include matching grants from the authorities and other partners, are worth up to S$18 million.

In 2015, we acquired Green Infra, a renewable energy company in India. This acquisition not only marked our entry into India’s renewable energy market, but also signified a major step in our strategy to grow our renewable business. In Myanmar, we were selected to develop the largest independent gas-fired power plant in the country. This project marked Sembcorp’s entry into Myanmar’s fast-growing power market. We also announced our entry into the Bangladesh power market and expanded our renewable energy business in Huanghua, China, with the development of two wind farms.

A strong push for innovation, coupled with a keen pursuit of growth opportunities, puts Sembcorp in an excellent position to build a strong future.

Going forward

The Group will maintain a disciplined approach to managing its financial position and portfolio. We will continue to deepen our asset management as well as business development and commercial capabilities, optimise plant performance and grow our asset portfolio for a greater recurring income base.

We will continue to identify and develop new and innovative technologies and leverage investments made for technologies relevant to our business. In addition, we will build on our culture of innovation through the recognition and implementation of !DEA Awards projects and other innovation proposals. In the near future, we expect to implement further phases of the Virtual Brain predictive maintenance and optimisation project and develop it for application to other water treatment processes. We will also continue to engage our partners in our ongoing projects, while scanning the landscape for more innovation opportunities.

Long-term economic viability is at the core of Sembcorp’s approach to building sustainable businesses. As we build successful, sustainable businesses, societies and communities benefit. Our businesses deliver the economic engine to support industrialisation and urbanisation. Our operations generate employment, contracts for local suppliers and tax revenues for governments and result in infrastructure development in our host communities. For more information on our contributions to communities, please refer to the Community section of this report. We drive our economic sustainability by monitoring and managing four key facets of our business: capital and portfolio management, reliability of our assets, products and services, innovation and business development for new income streams.

| * | On an accrued basis |

| ** | Figure is based on the reporting scope stated in the Sustainability Report, and includes Sembcorp Marine’s community contributions |

Capital and portfolio management

Sembcorp’s businesses often involve large-scale, long-term projects that require significant initial capital outlay. Strong financial health and a disciplined approach to investment are therefore necessary for us to succeed. At the same time, as Sembcorp continues to grow, we believe it is important for us to maintain a balanced portfolio of businesses across geographical regions and business segments, with the appropriate level of risk. Capital allocation, including the geographical distribution of our investments, is managed from this perspective.

Reliability

The reliability of our supply, assets and products is vital not only for our reputation, but also for our long-term profitability. Our Group is heavily invested in the Utilities business, which involves the development and sustained operation of energy and water facilities. We are committed to long-term customer contracts and our products and services, such as power, steam, water and wastewater treatment, are essential to our customers. By investing in the proper care and maintenance of our assets, we ensure that their useful life, and therefore their ability to generate stable recurring income and a reliable supply of products and services, is sustained throughout our long investment horizon.

Innovation

We recognise that technology and innovation is important in maintaining and enhancing our relevance, profitability and competitive advantage. This includes applied research and development (R&D) and improvements that optimise our operations and enhance our efficiency, as well as new technologies and methodologies that offer wider sustainability benefits.

New income streams

To deliver long-term growth, we continuously explore new business opportunities and maintain a pipeline of upcoming projects, which includes both greenfield and brownfield investments.

Positioned for Growth in the Right Businesses, in the Right Markets

As part of our strategy to ensure long-term growth, we continue to expand our operations overseas. In 2015, overseas contributions amounted to 60% of our Utilities business’ net profit excluding corporate costs and significant items.

We leveraged our strong development capabilities to grow through greenfield projects in rapidly developing economies, announcing our first energy projects in Myanmar and Bangladesh. In addition, we expanded our desalination capacity in the UAE and wind power assets in China. These projects, when completed, will provide us with new income streams.

We leveraged our strong development capabilities to grow through greenfield projects in rapidly developing economies, announcing our first energy projects in Myanmar and Bangladesh. In addition, we expanded our desalination capacity in the UAE and wind power assets in China. These projects, when completed, will provide us with new income streams.

Our approach

Capital and portfolio management

We have robust frameworks and processes in place to ensure our investment and business decisions take into account long-term considerations. In addition, potential acquisitions and growth opportunities are evaluated based on strict investment guidelines. Depending on criteria such as project value and country risk, approval for projects may involve the Senior Management Committee, the board and / or its Executive or Risk Committee.

We actively manage our risk portfolio, including monitoring balance sheet liquidity ratios and country risk profiles. For more information on risk management at Sembcorp, please refer to the Risk Management and Internal Controls chapter.

Reliability

Reliability of our assets, products and services

The reliability of our assets is of critical importance, and is rigorously managed from the design phase through to the operation and maintenance phase. In the design and construction phases, we focus on installing sufficient operational flexibility and selecting quality equipment. In the operation and maintenance phases, regulatory and manufacturers’ standards are strictly adhered to. The reliability of our plants is further monitored through monthly performance indicators which our management oversees. Technical audits and checks are also conducted on our plants.

Product safety and compliance

Product safety is a priority in our business, as non-compliance can result in serious health, safety and operational issues for our customers, many of whom depend on us for basic utilities or require our products for their industrial processes. We implement a robust maintenance and monitoring regime, which includes stringent inspections and the installation of meters and sensors at both our and our customers’ facilities. To ensure the safe delivery of our products, we have rigorous maintenance regimes in place and regularly inspect our delivery systems, including checking pipelines for leaks. We also conduct regular sampling and laboratory tests to meet regulatory requirements and to ensure that the water we produce is safe for our customers and end users.

Our Supply Chain

Sembcorp’s main suppliers consist of equipment manufacturers, raw material suppliers and engineering, procurement and construction (EPC) contractors.

Equipment manufacturers supply us with large-scale equipment such as gas turbines and desalination units as well as process equipment such as switchgears and control systems. Raw material suppliers supply fuel and chemicals needed to run our plants, while EPC contractors develop and construct our greenfield plants. Our plants are designed and built to have a long, productive lifespan, and it is with this perspective that we procure our equipment. We seek to ensure we procure high-quality and technologically advanced equipment that will last. We have stringent requirements for quality and therefore engage reputable suppliers who abide by global environmental, social and governance standards.

Our Group Procurement Policy provides guidelines and control principles for various stages of the procurement process.

We also recognise the importance of evaluating our suppliers to ensure supply chain risks and negative impacts are minimised. For example, our operations in Singapore carry out an annual vendor performance evaluation for our top suppliers by volume and dollar value. Through this process, we rate these suppliers on health, safety and the environment (HSE), as well as quality assurance and service level criteria. We also review their audited financial reports. In addition, for EPC contracts, contractors are assessed based on their track record with respect to project type, size and location experience, among other criteria. We value the opportunity to positively influence our suppliers towards greater HSE awareness and social responsibility. We believe that securing a pool of suppliers that share our commitment to sustainability will mitigate risks to our operations and reputation.

Supplier diversification

Our efforts to ensure supply chain security include diversifying supply to mitigate concentration risk. In Singapore, for instance, Sembcorp’s operations maintain at least one primary and one secondary supplier for key spare parts and consumables, wherever possible.

Fuel procurement

Fuel is a significant cost component for Sembcorp’s power and steam generation operations. The security of our fuel supply is also vital to the sustained performance of our assets. In view of this, we have a Group Fuel Management department that looks into issues such as security of supply, monitoring of price fluctuations and optimisation of fuel mix. To further diversify our fuel mix and tap sustainable sources, Sembcorp has increased our use of alternative fuels and renewables. In Singapore, for instance, our solid waste management operations provide a reliable supply of waste wood for our woodchip boiler plant. In our biomass power plant in the UK, waste wood from sustainably-managed forests and sawmills, as well as arboricultural residues, is used as fuel.

Sembcorp’s main suppliers consist of equipment manufacturers, raw material suppliers and engineering, procurement and construction (EPC) contractors.

Equipment manufacturers supply us with large-scale equipment such as gas turbines and desalination units as well as process equipment such as switchgears and control systems. Raw material suppliers supply fuel and chemicals needed to run our plants, while EPC contractors develop and construct our greenfield plants. Our plants are designed and built to have a long, productive lifespan, and it is with this perspective that we procure our equipment. We seek to ensure we procure high-quality and technologically advanced equipment that will last. We have stringent requirements for quality and therefore engage reputable suppliers who abide by global environmental, social and governance standards.

Our Group Procurement Policy provides guidelines and control principles for various stages of the procurement process.

We also recognise the importance of evaluating our suppliers to ensure supply chain risks and negative impacts are minimised. For example, our operations in Singapore carry out an annual vendor performance evaluation for our top suppliers by volume and dollar value. Through this process, we rate these suppliers on health, safety and the environment (HSE), as well as quality assurance and service level criteria. We also review their audited financial reports. In addition, for EPC contracts, contractors are assessed based on their track record with respect to project type, size and location experience, among other criteria. We value the opportunity to positively influence our suppliers towards greater HSE awareness and social responsibility. We believe that securing a pool of suppliers that share our commitment to sustainability will mitigate risks to our operations and reputation.

Supplier diversification

Our efforts to ensure supply chain security include diversifying supply to mitigate concentration risk. In Singapore, for instance, Sembcorp’s operations maintain at least one primary and one secondary supplier for key spare parts and consumables, wherever possible.

Fuel procurement

Fuel is a significant cost component for Sembcorp’s power and steam generation operations. The security of our fuel supply is also vital to the sustained performance of our assets. In view of this, we have a Group Fuel Management department that looks into issues such as security of supply, monitoring of price fluctuations and optimisation of fuel mix. To further diversify our fuel mix and tap sustainable sources, Sembcorp has increased our use of alternative fuels and renewables. In Singapore, for instance, our solid waste management operations provide a reliable supply of waste wood for our woodchip boiler plant. In our biomass power plant in the UK, waste wood from sustainably-managed forests and sawmills, as well as arboricultural residues, is used as fuel.

Innovation

Sembcorp’s Technology Advisory Panel, which includes our Chairman, Group President & CEO and other invited experts, provides strategic direction for our technology and innovation programmes. The panel oversees the development and application of significant emerging technologies in the energy and water sectors and provides guidance to Sembcorp’s leadership on technological trends and opportunities. It is supported by an in-house Group Technology department.

Headed by our Chief Technology Officer, our Group Technology department oversees our R&D and innovation efforts. Besides tracking our investment in innovation and its corresponding returns, we also track indicators such as the number of projects screened. This ensures that we have a pipeline of innovation projects being developed and implemented in a timely manner.

To further encourage innovation from bottom up, Sembcorp’s !DEA Awards programme rewards innovative ideas and efforts across the Group. Past winning entries have included process innovations that have resulted in cost savings and improved HSE performance, as well as innovations that have led to the development of new products and services.

Our ongoing engagement with venture capitalists, technology companies and tertiary research institutes helps us keep abreast of the latest technological advancements. In looking at new technology, we prioritise innovations that address the needs of our operations, but also consider more general proposals.

Promoting Clean Technology

Sembcorp pioneered the commercial reclamation of water from treated industrial and municipal wastewater effluent in Singapore. We have established ourselves as

a trusted wastewater treatment provider in Singapore as well as in industrial clusters in China. By integrating wastewater treatment, water reclamation and water supply in a closed loop, Sembcorp helps its customers reduce their water consumption and conserve this precious resource.

Sembcorp has also established a dedicated Renewables department to pursue clean technology opportunities. In 2015, Sembcorp acquired Green Infra, a leading renewable energy company in India, and expanded its wind power capacity in Huanghua, Hebei, China.

Sembcorp has also established a dedicated Renewables department to pursue clean technology opportunities. In 2015, Sembcorp acquired Green Infra, a leading renewable energy company in India, and expanded its wind power capacity in Huanghua, Hebei, China.

New income streams

Sembcorp’s Group Business Development & Commercial department is structured and equipped to pursue new business opportunities with agility and focus. Dedicated teams look into growing our businesses in both existing and new markets.

To ensure our continued growth, we identify and develop a healthy pipeline of projects. We also seek to grow through strategic partnerships with our customers, by continuously developing innovative and competitive solutions that meet their evolving needs.

We actively invest in sustainable and green business lines, which will give us an edge in an increasingly resource-scarce world. We take a disciplined approach and employ a stringent evaluation process to all our projects and investments.

Our performance

Sembcorp’s financial performance and key economic indicators can be found in our Group Financial Review chapter and Financial Statements.

As a global energy and water company with a rich history of being driven by technology and innovation, Sembcorp hopes to contribute towards raising Singapore’s profile as a hub for applied R&D, while supporting the long-term growth of the energy and water sectors. To this end, we have collaborated with several partners in various innovation projects. Ongoing partnerships include the Sembcorp Industrial Living Laboratory with the Singapore Economic Development Board and the Sembcorp-EMA Energy Technology Partnership with the Energy Market Authority (EMA) of Singapore. These projects leverage Sembcorp’s facilities for late-stage test-bedding and co-innovation of energy, water and environmental technologies, and explore the commercialisation of R&D solutions. The investments in these multi-year projects, which include matching grants from the authorities and other partners, are worth up to S$18 million.

In 2015, we acquired Green Infra, a renewable energy company in India. This acquisition not only marked our entry into India’s renewable energy market, but also signified a major step in our strategy to grow our renewable business. In Myanmar, we were selected to develop the largest independent gas-fired power plant in the country. This project marked Sembcorp’s entry into Myanmar’s fast-growing power market. We also announced our entry into the Bangladesh power market and expanded our renewable energy business in Huanghua, China, with the development of two wind farms.

A strong push for innovation, coupled with a keen pursuit of growth opportunities, puts Sembcorp in an excellent position to build a strong future.

Going forward

The Group will maintain a disciplined approach to managing its financial position and portfolio. We will continue to deepen our asset management as well as business development and commercial capabilities, optimise plant performance and grow our asset portfolio for a greater recurring income base.

We will continue to identify and develop new and innovative technologies and leverage investments made for technologies relevant to our business. In addition, we will build on our culture of innovation through the recognition and implementation of !DEA Awards projects and other innovation proposals. In the near future, we expect to implement further phases of the Virtual Brain predictive maintenance and optimisation project and develop it for application to other water treatment processes. We will also continue to engage our partners in our ongoing projects, while scanning the landscape for more innovation opportunities.

Governance, Risk and Compliance

To maintain high standards of behaviour and integrity and be best in class for governance practices

Why this is material

Governance and ethical business

Responsible business conduct ensures the long-term viability of our businesses and builds trust and confidence with our stakeholders. We commit to high standards of behaviour and integrity in everything we do, and comply with all laws and regulations wherever we operate. We believe in conducting our business legally, fairly, honestly and with integrity, and expect the same of those with whom we do business. Sembcorp has zero tolerance for fraud, bribery and corruption.

Risk and regulatory compliance

Risk management is an integral part of Sembcorp’s approach to operating sustainably. As we continue to grow and expand our global footprint, we are inadvertently exposed to diverse risks, such as political and regulatory, market, competition, supply chain, human resources, project and cost management risks, environmental and social risks, as well as the risk of possible fraud, corruption and bribery.

Besides helping to preserve our bottom line by reducing the likelihood and impact of potential losses, risk management provides a common basis on which to evaluate new business opportunities. It also assures our board and shareholders that key enterprise and business risks faced by the organisation have been identified, assessed and managed with appropriate risk mitigation and controls.

Sembcorp is committed to a high standard of regulatory compliance. Non-compliance with applicable laws and regulations may subject us to statutory and regulatory fines, resulting in material litigation. It may also affect our reputation, financials and licence to operate.

Our approach

Governance and ethical business

Sembcorp is led by an effective board mainly comprising of independent non-executive directors. The board is collectively responsible for the long-term success of the Group. Part of its role is to ensure that the Group’s internal control and risk management systems are adequate and effective, and that our obligations to key stakeholders are understood and met. Several board committees, including the board’s Risk Committee, have been established with clearly written terms of reference, both to assist the board in fulfilling its responsibilities, and to provide an independent oversight of management. The board’s Risk Committee has oversight of our Fraud Risk Management and Anti-Bribery and Corruption Policy.

Sembcorp complies with the Code of Corporate Governance 2012 issued by the Monetary Authority of Singapore, and reports our governance processes and activities with reference to the principles set out in it.

In addition, Sembcorp’s core values of Insight, Integral and Integrity define our approach to sustainable growth and form the foundation of Sembcorp’s Business Principles and Code of Business Conduct (CBC). Employees are required to comply with the requirements of the CBC, which addresses Sembcorp’s stance in the following areas:

Providing a fair, equitable workplace environment that is free from harassment

Corruption and bribery

Money laundering

Political contributions

Contributing to communities

Health, safety and the environment

Requirements of the CBC are communicated to employees globally through an e-learning course delivered in multiple languages. The CBC is also published on our website. Employees are required to acknowledge that they agree to abide by its principles and requirements and promptly report any violation through available reporting channels. Suppliers and contractors who work with Sembcorp are expected to respect and follow the CBC as well.

The standards of our CBC are also applied in our approach towards tax risk management. It is our policy to:

Observe compliance with relevant taxation laws and regulations and other regulatory disclosure requirements

Apply diligent professional care and judgement to arrive at well-reasoned recommendations, supplemented by advance rulings from tax authorities, written advice and confirmation from external tax advisors / experts, as appropriate

Ensure that all decisions are taken at an appropriate level and supported by a business purpose / commercial rationale and the appropriate documentation

Establish and maintain adequate documentation of the Group’s tax risk evaluation and tax risk management, and update the Group’s tax risk management policies including internal controls, as and when appropriate

Develop and foster good and respectful professional relationships with all tax authorities, government bodies and other related third parties

Risk and regulatory compliance

Risk management and system of internal controls

Sembcorp actively equips our management with tools to manage and control any risks associated with our existing business activities and investment decisions.

We also closely monitor key risk indicators as part of the requirements of our Risk Appetite Framework.

Our enterprise risk management (ERM) framework and GAF are aligned with best practice standards such as ISO31000 and standards issued by the Committee of Sponsoring Organizations of the Treadway Commission (COSO).

The Group’s risks and monitoring of internal controls are managed through:

Periodic review and reporting of corporate and operational risks and controls through detailed risk and controls registers

Review of major occurrences, key risk areas and significant control lapses at business unit management meetings and risk management committee meetings

Risk assessments at the investment appraisal and due diligence stages

Monitoring of key risks and control lapses through a quarterly governance assurance certification submission

An internal controls policy and manual have also been established to provide a clear framework for what constitutes an effective and adequate system of internal controls. They also provide guidelines on the appropriate segregation of duties and a checklist of recommended internal controls for our business units to put in place.

Internal audits are regularly performed based on an approved audit work plan, and cover high-risk areas such as possible fraud, bribery and corruption.

Emergency response plans are in place and crisis simulation exercises are conducted to ensure that we are adequately prepared for foreseeable emergencies. This is to ensure that in the event of an emergency, we are better able to handle the crisis and can minimise any negative impacts.

For more information on Sembcorp’s governance and risk management systems, please refer to our Corporate Governance Statement and Risk Management and Internal Controls chapter.

Training and performance management

The Group provides awareness training and workshops on ERM, GAF, as well as fraud risk management and business continuity management on a periodic basis. Desktop exercises and simulation for crisis management, emergency response drills and business continuity exercises are also conducted regularly to validate and fine-tune our procedures and plans and improve our preparedness.

In order to enhance corporate governance and risk management excellence at Sembcorp, key risk and governance performance indicators have been identified and incorporated as part of the remuneration requirements for senior management. For more details on senior management remuneration and reward, please refer to our Corporate Governance Statement.

Our performance

Through the successful global roll-out of two e-learning courses on anti-bribery, corruption and the CBC, we continued to emphasise the importance of fraud risk management and measures to guard against the risk of bribery and corruption in our business. Employees are required to pass a test to affirm their knowledge and understanding of the subject. They are also required to acknowledge that they agree to abide by the principles and the requirements of the CBC. We continued to communicate our zero tolerance for fraud, bribery and corruption to our employees and engage them on our whistle-blowing policy and guidelines through fraud awareness workshops with updated case studies and training sessions.

Sembcorp received the Most Transparent Company Award in the oil and gas category at the Securities Investors Association (Singapore) Investors’ Choice Awards 2015. We were also ranked sixth in the 2015 edition of the Governance & Transparency Index, a well-respected index assessing the transparency of 639 Singapore-listed companies.

Two significant incidents resulting in fines amounting to S$109,000 were incurred by our operations in Chile for non-compliance to water quality and discharge standards. Additional treatment plants as well as facility enhancements have been installed to ensure non-recurrence. Our operations in Singapore incurred a penalty of S$50,000 due to an unsuccessful gas turbine fuel changeover.

As part of our ongoing effort to build in-house capabilities, readiness and resilience to crisis and emergency response situations, we have conducted regular crisis simulation exercises and awareness trainings. Notably, we successfully conducted an exercise simulating a raw water contamination incident at our Fuzhou municipal water operations. This exercise was conducted in partnership with the local authorities, and received media coverage highlighting Sembcorp and the local government’s resolve in being prepared for such incidents. In Singapore, we also successfully conducted a crisis preparedness exercise simulating a pipeline leakage and used our incident management system to monitor the incident remotely from the crisis command centre. The exercise included involvement of the Singapore Civil Defence Force and a customer that would be affected by such an incident.

Going forward

We understand that the pursuit of excellence in corporate governance and risk management is a continuous journey. Hence, we will continue to strengthen our frameworks and policies to align them with industry best practice. To build a positive risk and governance culture, we will continue to communicate and engage our employees and stakeholders through continuous awareness workshops and training sessions. We will also provide the right systems and tools to enhance the risk management and governance process.

Governance and ethical business

Responsible business conduct ensures the long-term viability of our businesses and builds trust and confidence with our stakeholders. We commit to high standards of behaviour and integrity in everything we do, and comply with all laws and regulations wherever we operate. We believe in conducting our business legally, fairly, honestly and with integrity, and expect the same of those with whom we do business. Sembcorp has zero tolerance for fraud, bribery and corruption.

Risk and regulatory compliance

Risk management is an integral part of Sembcorp’s approach to operating sustainably. As we continue to grow and expand our global footprint, we are inadvertently exposed to diverse risks, such as political and regulatory, market, competition, supply chain, human resources, project and cost management risks, environmental and social risks, as well as the risk of possible fraud, corruption and bribery.

Besides helping to preserve our bottom line by reducing the likelihood and impact of potential losses, risk management provides a common basis on which to evaluate new business opportunities. It also assures our board and shareholders that key enterprise and business risks faced by the organisation have been identified, assessed and managed with appropriate risk mitigation and controls.

Sembcorp is committed to a high standard of regulatory compliance. Non-compliance with applicable laws and regulations may subject us to statutory and regulatory fines, resulting in material litigation. It may also affect our reputation, financials and licence to operate.

Communicating Our Code of Business Conduct Through Electronic Learning

The Sembcorp Code of Business Conduct expresses the high standards of behaviour and integrity expected from our employees worldwide.

An e-learning course in multiple languages was launched globally to further communicate our Code of Business Conduct and help employees better understand its requirements, guiding principles and application in their daily course of work.

An e-learning course in multiple languages was launched globally to further communicate our Code of Business Conduct and help employees better understand its requirements, guiding principles and application in their daily course of work.

Our approach

Governance and ethical business

Sembcorp is led by an effective board mainly comprising of independent non-executive directors. The board is collectively responsible for the long-term success of the Group. Part of its role is to ensure that the Group’s internal control and risk management systems are adequate and effective, and that our obligations to key stakeholders are understood and met. Several board committees, including the board’s Risk Committee, have been established with clearly written terms of reference, both to assist the board in fulfilling its responsibilities, and to provide an independent oversight of management. The board’s Risk Committee has oversight of our Fraud Risk Management and Anti-Bribery and Corruption Policy.

Sembcorp complies with the Code of Corporate Governance 2012 issued by the Monetary Authority of Singapore, and reports our governance processes and activities with reference to the principles set out in it.

In addition, Sembcorp’s core values of Insight, Integral and Integrity define our approach to sustainable growth and form the foundation of Sembcorp’s Business Principles and Code of Business Conduct (CBC). Employees are required to comply with the requirements of the CBC, which addresses Sembcorp’s stance in the following areas:

Requirements of the CBC are communicated to employees globally through an e-learning course delivered in multiple languages. The CBC is also published on our website. Employees are required to acknowledge that they agree to abide by its principles and requirements and promptly report any violation through available reporting channels. Suppliers and contractors who work with Sembcorp are expected to respect and follow the CBC as well.

The standards of our CBC are also applied in our approach towards tax risk management. It is our policy to:

Risk and regulatory compliance

Risk management and system of internal controls

Sembcorp actively equips our management with tools to manage and control any risks associated with our existing business activities and investment decisions.

We also closely monitor key risk indicators as part of the requirements of our Risk Appetite Framework.

Our enterprise risk management (ERM) framework and GAF are aligned with best practice standards such as ISO31000 and standards issued by the Committee of Sponsoring Organizations of the Treadway Commission (COSO).

The Group’s risks and monitoring of internal controls are managed through:

An internal controls policy and manual have also been established to provide a clear framework for what constitutes an effective and adequate system of internal controls. They also provide guidelines on the appropriate segregation of duties and a checklist of recommended internal controls for our business units to put in place.

Internal audits are regularly performed based on an approved audit work plan, and cover high-risk areas such as possible fraud, bribery and corruption.

Emergency response plans are in place and crisis simulation exercises are conducted to ensure that we are adequately prepared for foreseeable emergencies. This is to ensure that in the event of an emergency, we are better able to handle the crisis and can minimise any negative impacts.

For more information on Sembcorp’s governance and risk management systems, please refer to our Corporate Governance Statement and Risk Management and Internal Controls chapter.

Training and performance management

The Group provides awareness training and workshops on ERM, GAF, as well as fraud risk management and business continuity management on a periodic basis. Desktop exercises and simulation for crisis management, emergency response drills and business continuity exercises are also conducted regularly to validate and fine-tune our procedures and plans and improve our preparedness.

In order to enhance corporate governance and risk management excellence at Sembcorp, key risk and governance performance indicators have been identified and incorporated as part of the remuneration requirements for senior management. For more details on senior management remuneration and reward, please refer to our Corporate Governance Statement.

Our performance

Through the successful global roll-out of two e-learning courses on anti-bribery, corruption and the CBC, we continued to emphasise the importance of fraud risk management and measures to guard against the risk of bribery and corruption in our business. Employees are required to pass a test to affirm their knowledge and understanding of the subject. They are also required to acknowledge that they agree to abide by the principles and the requirements of the CBC. We continued to communicate our zero tolerance for fraud, bribery and corruption to our employees and engage them on our whistle-blowing policy and guidelines through fraud awareness workshops with updated case studies and training sessions.

Sembcorp received the Most Transparent Company Award in the oil and gas category at the Securities Investors Association (Singapore) Investors’ Choice Awards 2015. We were also ranked sixth in the 2015 edition of the Governance & Transparency Index, a well-respected index assessing the transparency of 639 Singapore-listed companies.

Two significant incidents resulting in fines amounting to S$109,000 were incurred by our operations in Chile for non-compliance to water quality and discharge standards. Additional treatment plants as well as facility enhancements have been installed to ensure non-recurrence. Our operations in Singapore incurred a penalty of S$50,000 due to an unsuccessful gas turbine fuel changeover.

As part of our ongoing effort to build in-house capabilities, readiness and resilience to crisis and emergency response situations, we have conducted regular crisis simulation exercises and awareness trainings. Notably, we successfully conducted an exercise simulating a raw water contamination incident at our Fuzhou municipal water operations. This exercise was conducted in partnership with the local authorities, and received media coverage highlighting Sembcorp and the local government’s resolve in being prepared for such incidents. In Singapore, we also successfully conducted a crisis preparedness exercise simulating a pipeline leakage and used our incident management system to monitor the incident remotely from the crisis command centre. The exercise included involvement of the Singapore Civil Defence Force and a customer that would be affected by such an incident.

Going forward

We understand that the pursuit of excellence in corporate governance and risk management is a continuous journey. Hence, we will continue to strengthen our frameworks and policies to align them with industry best practice. To build a positive risk and governance culture, we will continue to communicate and engage our employees and stakeholders through continuous awareness workshops and training sessions. We will also provide the right systems and tools to enhance the risk management and governance process.

People

To provide a fair, diverse and inclusive workplace, and continually improve our human resource management and people development

Why this is material

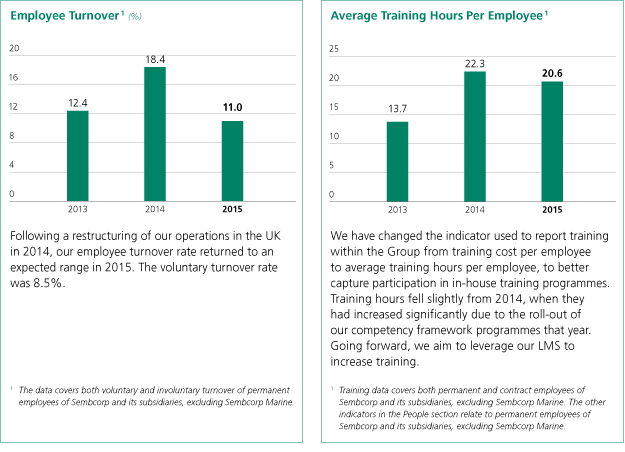

Our employees play a vital role in ensuring we achieve our business strategy and goals. Of the issues relating to our people, such as fair employment, labour relations and human rights, we have identified people development to be the most material.

People development

To be a high-performance organisation, it is crucial to develop a competent, capable and motivated workforce that can meet the business challenges of today and tomorrow.

The nature of our business is such that we require specialist technical expertise. However, some of the markets in which we operate lack a qualified labour force with the necessary technical skill sets that our business demands. In other markets, these skill sets are highly sought after across several industries. In addition, the commercial and regulatory environment we operate in is also becoming increasingly complex. Therefore, there is a critical need to attract, retain and develop competent employees who possess a deep understanding of the company and its industry sectors.

Our approach

Human resource policies and management

The Senior Management Committee, supported by the Group Human Resources department, is responsible for setting key policies relating to our employees.

Country-specific human resource policies, as well as all other company policies and guidelines, are available and accessible to employees on our intranet.

We stay abreast of the latest developments and best practice for human resource management through our membership and participation in external organisations such as the Singapore National Employers Federation, the Temasek Human Resource Council and The Conference Board, as well as numerous local roundtable groups.

Further details on our approach and initiatives on labour relations, remuneration and employee welfare and engagement can be found in the People portion of the Sustainability section of our website.

Human rights and labour relations

The Group is committed to uphold and respect the spirit of the UN Universal Declaration of Human Rights and the International Labour Organisation’s Declaration on Fundamental Principles and Rights at Work. We fully support the UN Global Compact principles on human rights and labour, and abide by the Employers’ Pledge of Fair Employment Practices under Singapore’s Tripartite Alliance for Fair and Progressive Employment Practices. Our CBC sets out our stand on fairness, opportunity, non-discrimination, dignity, respect and harassment. We do not hire forced or child labour, and comply with local regulations restricting forced or child labour wherever we operate. While our operations span five continents where labour laws, regulations and practices differ widely, we remain committed to high standards of human resource management globally. We abide by local laws wherever we operate, including meeting or exceeding minimum wage requirements where such requirements exist. Examples of other regulations our global operations comply with include the Broadbased Black Economic Empowerment Amendment Act 2013 in South Africa, and localisation requirements at our operations in Oman and the UAE.

We recognise the value and benefit of mutual discussion. Our grievance handling policy seeks to manage employee grievances in a fair and reasonable manner, with an escalation path to the Group President & CEO where necessary. We seek to maintain good labour management relations, and hold constructive ongoing exchanges with employee unions in our various operations. All Sembcorp employees are entitled to practise freedom of association and to be covered by collective agreements in the workplace, within the regulatory boundaries of each of the jurisdictions in which we operate. In countries where our operations are covered by collective agreements, procedures for grievance handling are specified in the agreements.

People development

People development is driven at the board level by the Executive Resource & Compensation Committee.

Our “My Career Journey @ Sembcorp” programme guides the identification, development and deployment of employees across the organisation. The programme encompasses three aspects:

Employee learning and development

Employees at Sembcorp are empowered to be responsible for their learning and development, supported by their supervisors.

Our engineers and technicians receive up-to-date technical training by experts. All employees are also encouraged to attend relevant professional courses.

We offer our employees the opportunity to develop their careers and gain international exposure through job rotations and attachments in different cultural and operational settings. We currently have more than 50 employees of different nationalities seconded from our Singapore offices to various overseas operations. We also provide internships and industrial attachments that offer students and Sembcorp scholars practical experience and exposure to our operations.

We support our employees in their pursuit of continuous improvement and sponsor selected employees who wish to pursue higher qualifications in fields relevant to their work. To develop our leaders, we sponsor senior executives’ enrolment in programmes at leading institutes such as Harvard Business School, The University of Pennsylvania Wharton School, INSEAD and Temasek’s Business Leadership Centre. Sembcorp scholarships are also offered to promising students at various tertiary institutions. Once they graduate, a comprehensive development plan is mapped out to groom them for management positions.

As a leader in our industry sectors, Sembcorp encourages our employees to share and exchange best practices through seminars, roadshows and local and international conferences.

Developing local capability

We believe in recruiting, grooming and retaining local talent as a long-term investment in our future and an integral part of our strategy for our overseas operations. This leads to knowledge transfer and capability development in the local community.

Localisation is an important part of our strategy to grow our overseas projects sustainably. We aim to progressively localise the workforce at our overseas operations across all positions, including management positions, in line with each jurisdiction’s regulatory and operating environment. When we begin operating in a new market, employees who are seconded from our head office to start up the operations are given a clear responsibility to develop local talent. As the capabilities of local employees grow, the team is gradually localised, and the number of expatriates seconded from head office progressively reduced.

All employees across the Group are offered the same development opportunities. At our overseas operations, local employees are also encouraged to develop their professional and managerial skills through international exposure, such as on-the-job training in Singapore or at other Sembcorp operations around the world.

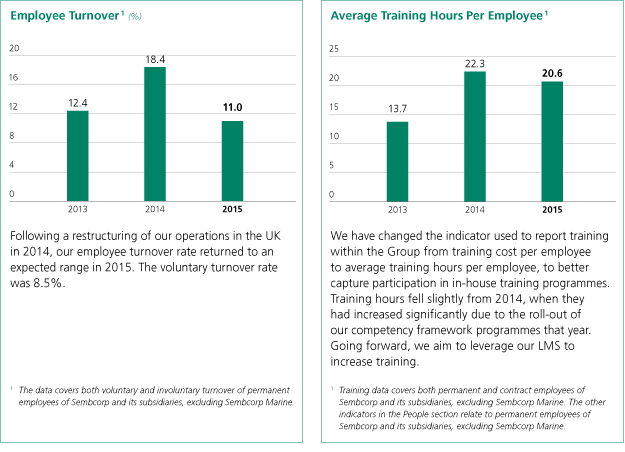

Performance appraisals